Step 1

Requirement collection

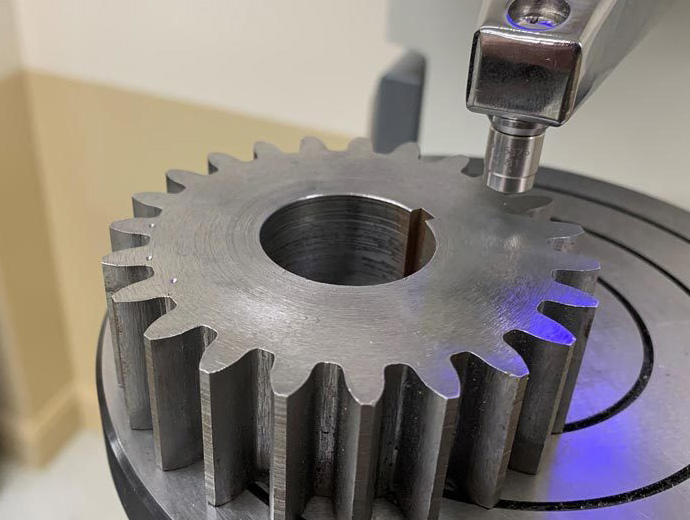

Customers provide design requirements, drawings, or samples.

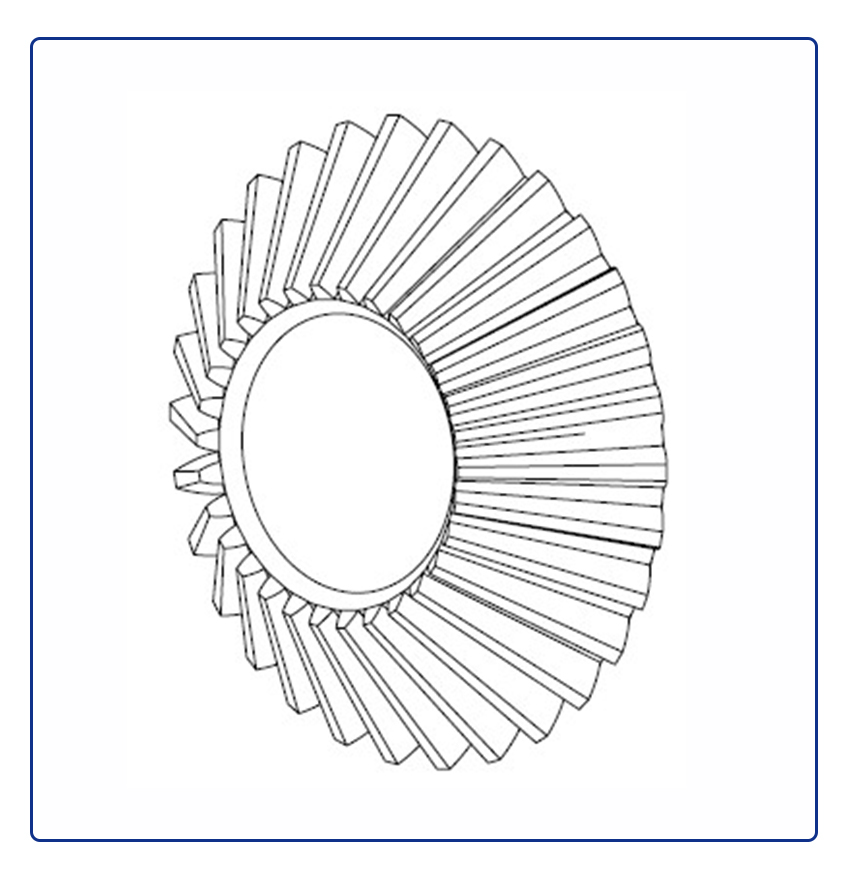

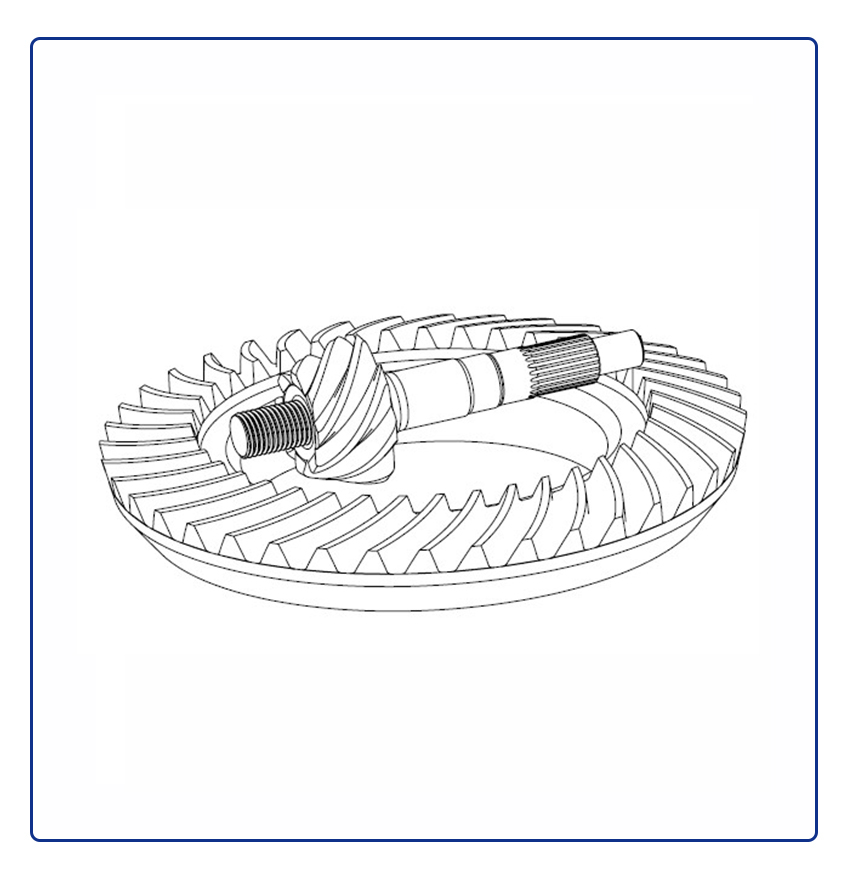

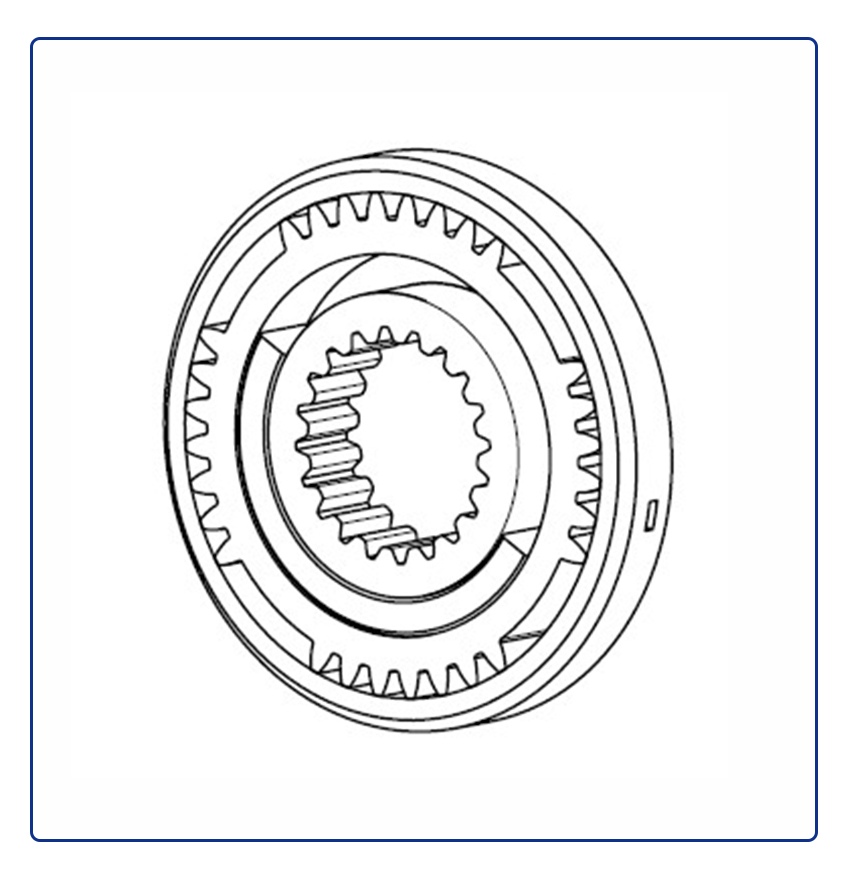

Before embarking on the journey to create your ideal precision gear, we sincerely invite you to stay here and learn more about our customized journey. Every gear is a masterpiece of precision craftsmanship, designed to transform your mechanical dreams into reality. Whether it is promoting the efficient operation of agriculture, driving commercial vehicles and construction machinery with powerful power, or inspiring revolutionary innovations in tram drive motors, we provide professional customization services to ensure that each product can meet your precise requirements. need.

Customers provide design requirements, drawings, or samples.

PairGears draws and optimizes drawings based on customer's 2D drawings or samples, and sends them to customers for confirmation.

After the customer confirms the drawings, we can provide an accurate quotation.

After price confirmation, we will arrange the production of tools and molds. Customers need to pay for the tooling and mold costs upfront, which will be refunded after bulk ordering.

After the tooling and molds are finalized, we will complete the production of the first sample within 30 days and send it to the customer for inspection.

Upon receiving the sample, customers will inspect and verify the first sample, and provide feedback on the inspection results to us.

Once the customer confirms the sample is qualified, we will begin mass production.

After production is completed, we will inspect the products for hardness, dimensions, runout, etc., to ensure 100% product compliance.

When the inspection results are OK and the customer confirms the shipment can proceed, we will arrange the booking and shipping.

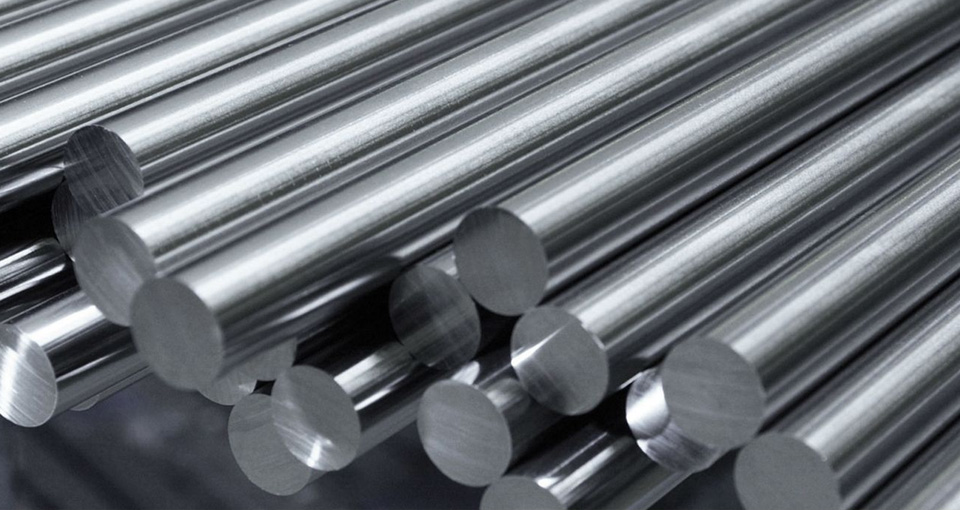

Material selection is the foundation to ensure the performance and quality of gear products. We provide a variety of material options to meet the needs of different industries for products.

If you want to customize other special materials, pleasecontact us.

20MnCr5 is an alloy carburized steel, with high strength and toughness, and good hardenability. The performance after heat treatment is better than 20Cr. The quenching deformation is small, the low temperature toughness is good, and the machinability is good; but the welding performance is low. Generally used after carburizing, quenching or quenching and tempering.

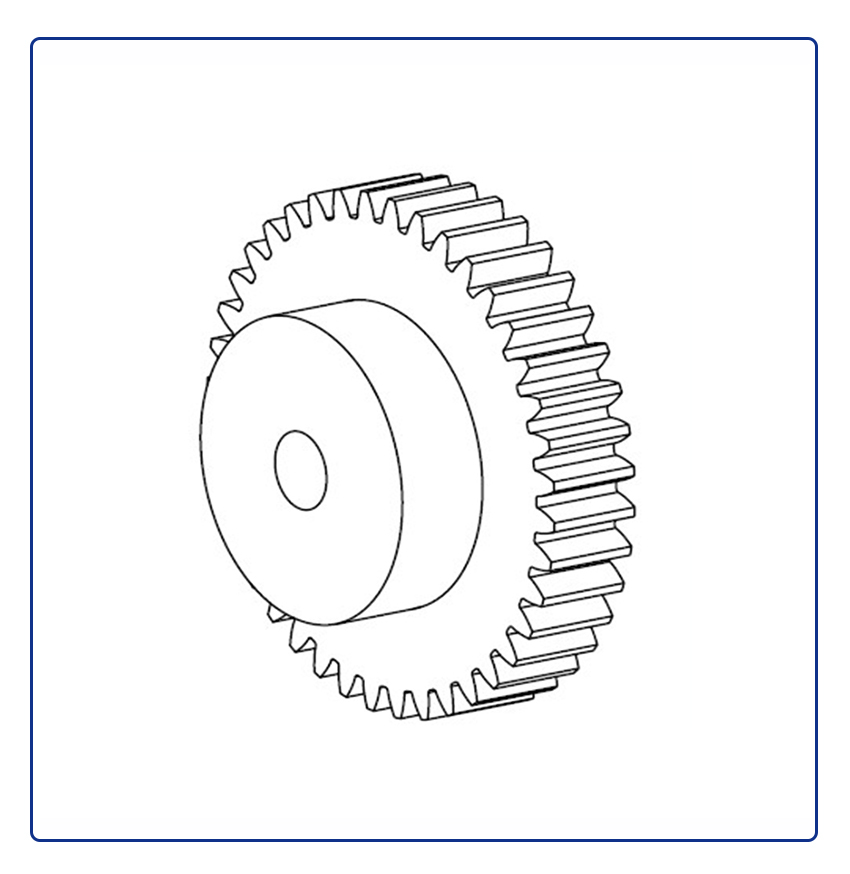

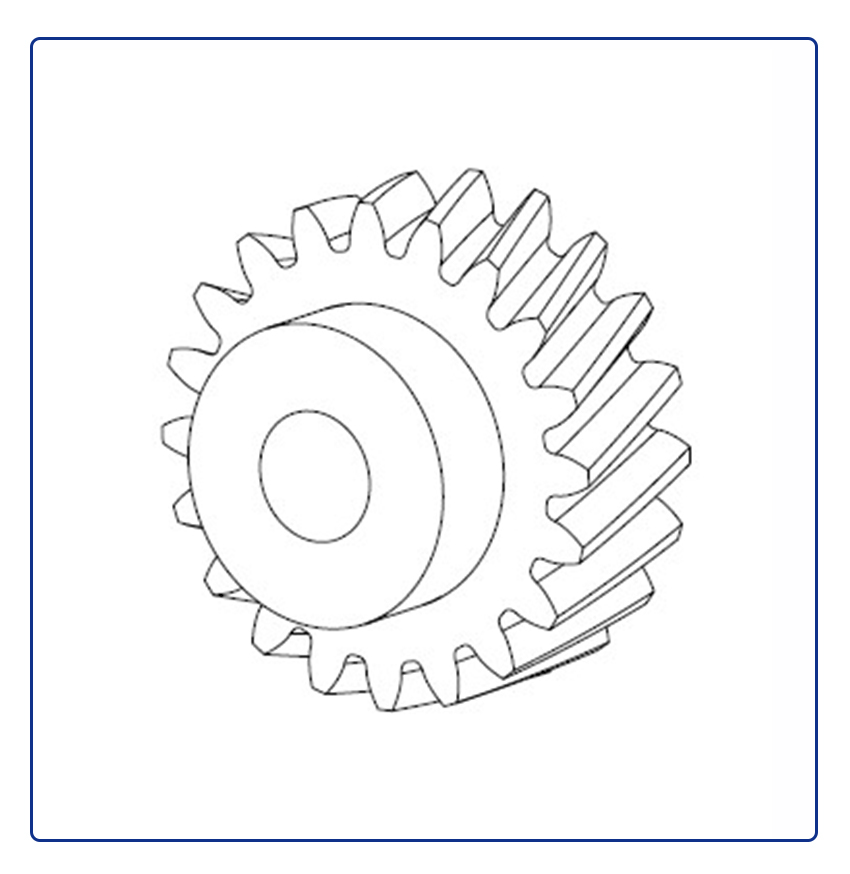

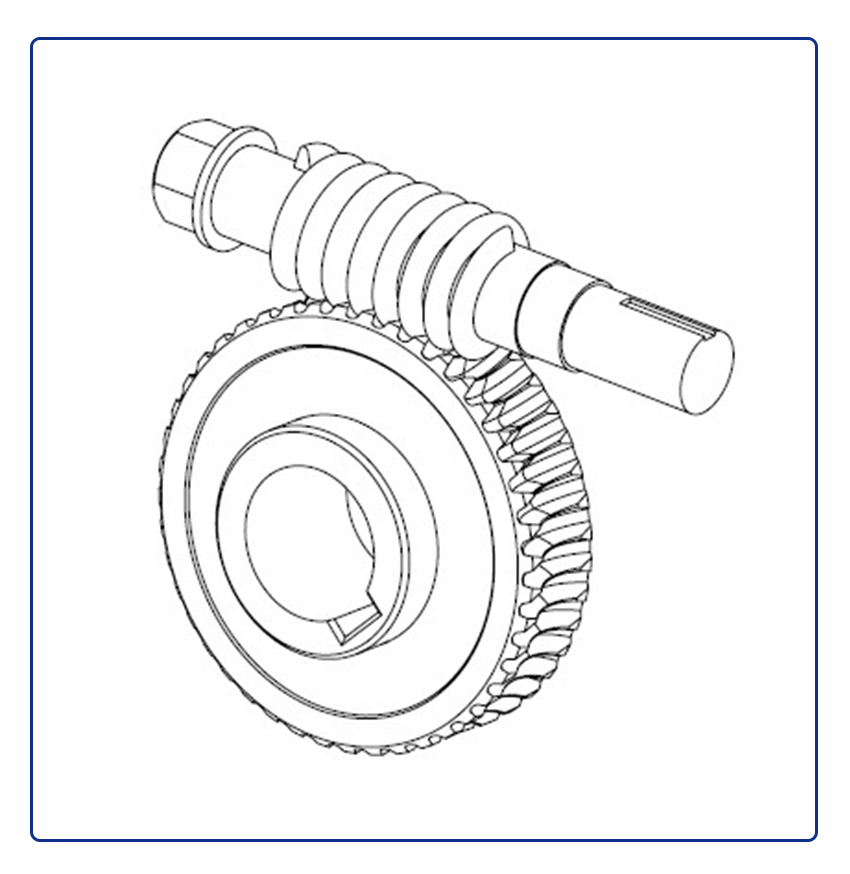

Used for manufacturing and heavy-duty hardened and tempered parts with large cross-sections and carburized parts with small cross-sections. It can also be used to manufacture small and medium-sized parts with medium load and low impact, instead of 20CrNi, such as gears, shafts, spindles, and friction wheels for variable speed equipment. , Worm, governor sleeve, etc.

20CrMnTi is a carburized steel with high level properties. After carburizing and quenching, it has a hard and wear-resistant surface and a tough core. Under the condition of ensuring hardenability, it has high low-temperature impact toughness. Medium weldability, good machinability after normalizing. After surface carburizing and hardening treatment, 20CrMnTi steel has good workability, small processing deformation, and good fatigue resistance.

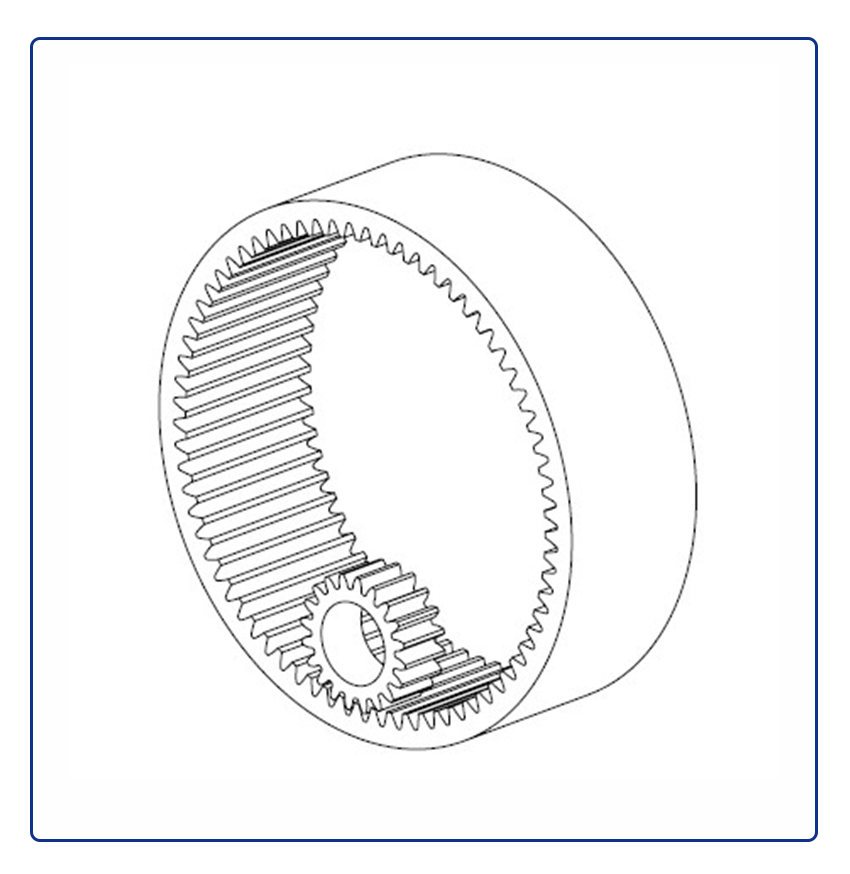

The main uses are for shafts, piston parts and various special parts of automobiles and airplanes. It is used to manufacture important parts with a cross section of <30mm that are subject to high speed, medium or heavy load, impact and friction, such as gears, ring gears, gear shaft crossheads, etc. It is a substitute steel of 18CrMnTi, mainly used for shafts, piston parts and various special parts of automobiles and airplanes. It is also widely used as carburizing parts. In the automobile and tractor industries, it is used to make important carburized parts with a cross-section below 30mm, high speed, medium or heavy load, and impact and friction, such as gears, shafts, ring gears, gear shafts. Sliding bearing main shaft, cross head, claw clutch, worm, etc.

SAE 8620 is American Standard alloy steel used for mould, gear, shafts etc, belongs to standard ASTM A29/A29M-04 . Equivalent to the Chinese standard 20NiCrMo2 steel, is a Cr-Ni-Mo case hardening steel widely used in carburizing and carbonitriding. SAE 8620 has high hardenability, no temper brittleness, good weldability, little tendency to form cold cracks, good machinability and cold strain plasticity. Generally used in quenched and tempered or carburized and quenched state, it is used to manufacture high-pressure pipes and various fasteners that work in non-corrosive media and media containing nitrogen and hydrogen mixtures with a working temperature of less than 250 ℃, and higher-level infiltration Carbon parts, such as gears, shafts, etc.

SAE 1045 is a high-quality carbon structural steel. It is a common type of steel used in various applications due to its good combination of strength, toughness, and wear resistance. SAE 1045 has a carbon content of approximately 0.42-0.50%, which provides it with the necessary hardness and strength properties.

SAE 1045 is widely used in the manufacturing of machinery parts, gears, axles, shafts, bolts, studs, and other components that require moderate strength, hardness, and wear resistance. It can be readily welded and machined using conventional techniques, making it versatile for different fabrication processes.

SAE 4140 steel belongs to the ultra-high-strength steel, with high strength and toughness, hardenability is also good, no significant temper brittleness, after quenching and tempering have higher fatigue limit and anti-repeated impact ability, low temperature impact toughness . The steel suitable for the manufacture of a certain strength and toughness of large and medium-sized plastic mold. Equivalent to the Chinese standard 42CrMo steel.

SAE5120 alloy structural steel, equivalent to China GB Standard Grade 20Cr, is mainly used for mechanical parts and various engineering components and contains one or several certain amount of alloying elements. SAE5120 alloy structural steel has suitable hardenability, after suitable metal heat treatment, the microstructure is uniform sorbite, bainite or very fine pearlite, so it has high tensile strength and yield strength. Ratio (usually around 0.85), higher toughness and fatigue strength, and lower toughness-brittle transition temperature, can be used to manufacture machine parts with larger cross-sectional dimensions.

40Cr is one of the most popular steel grades in the industry. After Q T heat treatment, it usually is used to make parts. Such as the gears of machine tools, shaft, worm, spline shaft and etc. If it is through quenching and tempering; high-frequency quenching, it will be good choice for fittings with high hardness and wear resistance. For example, wheel gear, shaft, principal axis, crankshaft, arbor, inlet valve, bolt and etc.

Gears and shafts made of 40Cr material can be treated with nitriding heat treatment process to reduce product deformation. So it is commonly used to replace materials such as 20MnCr5 and 20CrMnTi, and to produce products such as gears, gear rings, and shafts that are prone to deformation during heat treatment and require high precision.

SCM440 is a commonly steel grade which used for the production of high-strength fasteners and gears. The product has the advantages of stable composition, low harmful elements, high steel purity, small decarburization layer, and few surface defects. It is easy to perform spheroidizing annealing and cooling during use. The upsetting cracking rate is low, the heat treatment quality is stable, and the hardness is uniform.

It is widely used in engines, molds and other industries. It can replace with 42CrMo in China and 42CrMo4 in Germany. It belongs to medium hardenability steel, has good strength and good comprehensive mechanical properties after heat treatment, good manufacturability, and high yield rate. The maximum operating temperature is 427℃. Can be used as a steam turbine fastener.

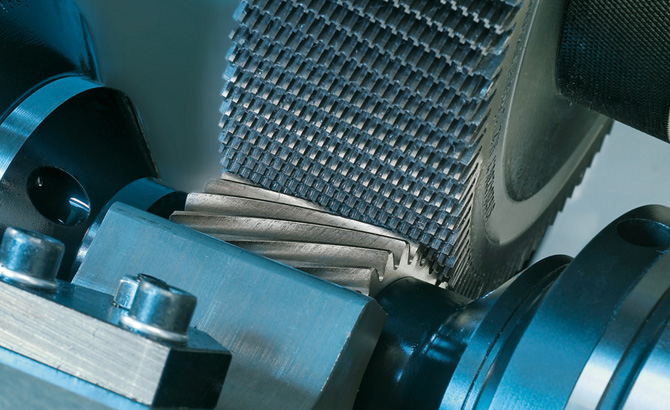

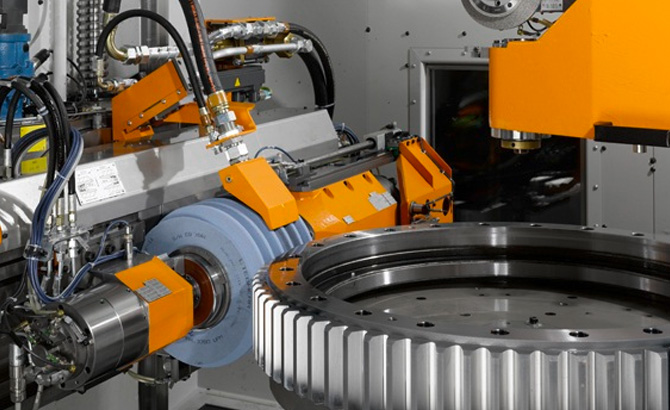

Shaving can achieve accuracy levels of 7-9.

while grinding can achieve levels of 4-6.

Case hardening is a process which involves adding a hard, protective shell to the outside of an otherwise soft steel. This process allows for intricately shaped metals to possess a strength and toughness that they otherwise wouldn't be able to possess.

The nitriding process takes place at lower temperatures than carburizing treatment, which makes it very suitable in the construction of gears to limit the deformation during the heat treatment process. Increase the surface hardness of the steel, improving its resistance to fatigue and wear.

The high-frequency quenching gear is characterized in that the core has high strength and high impact toughness after high-frequency quenching, tooth surface has high hardness and high abrasion resistance, and the high-frequency quenching gear can pass a 720-hour fatigue test.