Comprehensive Guide to Custom Differential Gear Services

1. Introduction

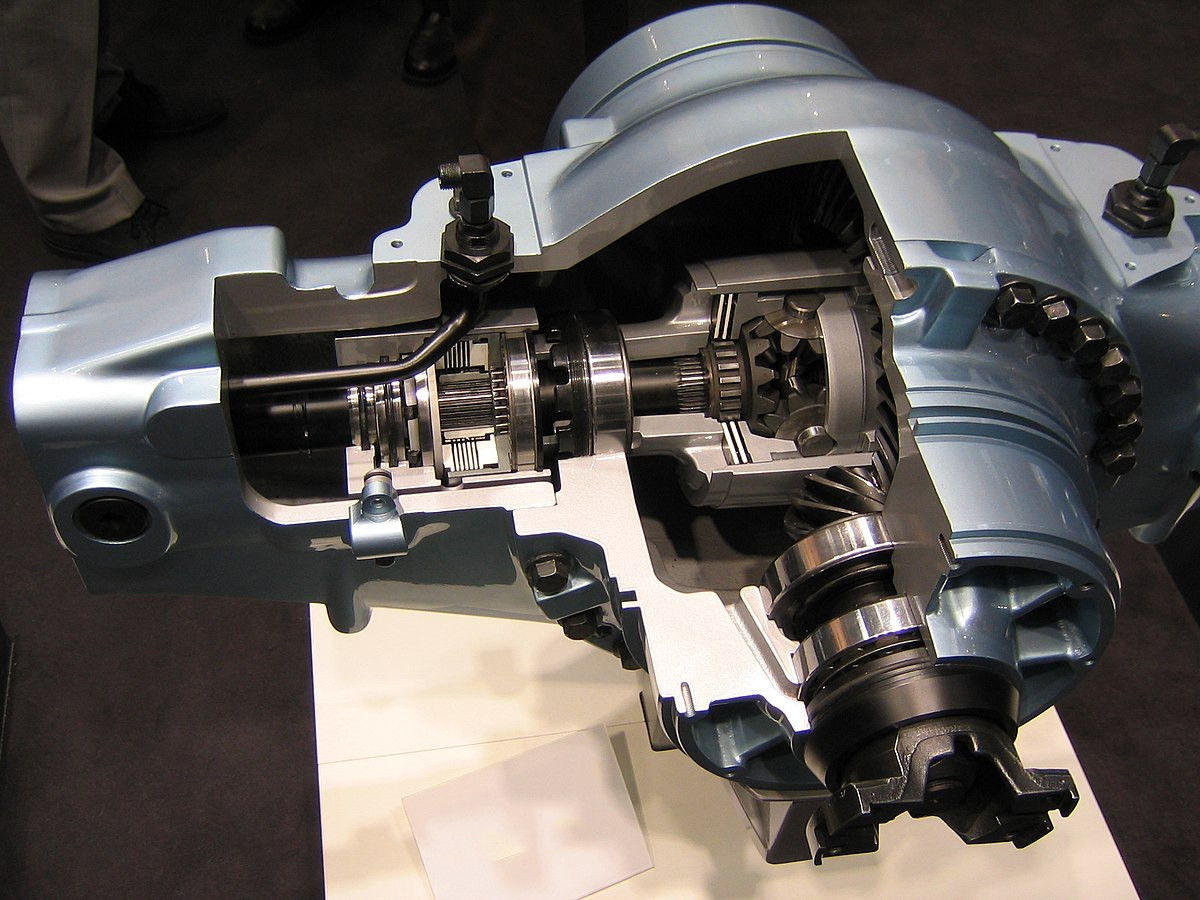

1.1 What Is a Differential Gear and Why Customization Is Critical

A differential gear is a vital part of a vehicle's drivetrain, enabling wheels to rotate at different speeds when turning. Precision in custom differential gear design is essential to ensure optimal torque distribution, minimal wear, and vehicle safety.

1.2 Why Choose Custom Differential Gears?

Standard solutions may not meet the specific load, torque, or dimensional requirements of specialty vehicles or industrial machinery. With custom differential gear manufacturing, you can tailor tooth geometry, material hardness, and even compatibility with limited-slip or locking systems. Learn more at PairGears.

2. Benefits of Custom Differential Gears

2.1 Enhanced Torque Management

Optimized designs improve torque transmission in off-road, racing, or load-bearing environments.

2.2 Noise and Vibration Reduction

Custom tooth profiles and machining reduce vibration and improve drivetrain smoothness.

2.3 Increased Durability

Material upgrades and thermal treatments boost fatigue resistance and operational life.

3. Our Custom Differential Gear Services

3.1 Fully Customized Designs

We offer bespoke designs that include:

• Ring and pinion gear sizing

• Gear ratios

• Hypoid vs. spiral bevel configurations

• Compatibility with locking differentials

3.2 Material Selection

• 8620/9310 case-hardening alloy steel

• Carburized & induction-hardened options

• Heat-treated forged steel for performance applications

3.3 Gear Specifications Supported

• Modules and diametral pitch

• Spiral angle and pressure angle

• Face width and backlash tuning

3.4 Advanced Surface Treatment

• Shot peening

• Lapping and gear grinding

• Phosphate coating or black oxide

3.5 Manufacturing Excellence

• 5-axis CNC hobbing & grinding

• In-house heat treatment

• Laser marking and hardness testing

3.6 Lead Times & Project Management

With advanced planning tools, we offer rapid prototypes and full-scale production with timely delivery.

4.1 Critical Gear Parameters

Including tooth count, backlash, helix angle, and pitch diameter—all affecting performance, efficiency, and noise.

4.2 Material Science Considerations

Selection of alloys depends on application: e.g., high-nickel steel for performance cars vs. carbon steel for agricultural vehicles.

4.3 Manufacturing Workflow

4.3.1 Gear blank machining

4.3.2 Heat treatment & stress relieving

4.3.3 Finishing (grinding, shaving)

4.3.4 Assembly and final inspection

4.4 Surface Finishing and Performance

Proper finishing improves oil retention, reduces friction, and enhances long-term reliability.

5.1 In-Depth Testing

• Gear contact pattern check

• Tooth hardness testing (Rockwell/C scale)

• Precision measurement (AGMA/DIN standards)

5.2 Smart Monitoring

Digital systems trace manufacturing tolerances and process deviations in real time.

5.3 Certifications

PairGears is ISO 9001 certified and adheres to CE compliance for relevant gear products.

6. Applications

6.1 Automotive Industry

Performance vehicles, trucks, off-road 4x4s.

6.2 Industrial Machinery

Loaders, graders, and mining transport systems.

6.3 Agricultural Equipment

Harvesters, tractors, and sprayers.

6.4 Specialty Vehicles

EV platforms, defense vehicles, and custom industrial drivetrains.

7. Case Studies

7.1 OEM Truck Application

Custom ring & pinion for torque-heavy payload.

7.1 Racing Car Builder

Limited-slip differential configuration with high-strength alloys.

7.1 Agricultural Driveline

Durable bevel gear system for harsh field conditions.

Q1: What is the MOQ for custom differential gears?

A1: Minimum order depends on size and complexity; low-volume production available.

Q2: Lead time for custom orders?

A2: Typically 15–30 working days depending on requirements.

Q3: Can I request specific gear ratios or axle configurations?

A3: Yes, all specifications including ratio, backlash, and fit are customizable.

Q4: Do you provide test data or samples?

A4: Test reports and samples are available upon request.

Q5: Are there after-sales or consultation services?

A5: Yes, PairGears provides full engineering support pre- and post-sale.

9. Start Your Project

9.1 Contact us via Contact Page

9.1.1 Submit drawing or requirements

9.1.2 Technical consultation & quotation

9.1.3 Confirm specs and initiate production

9.1.4 Delivery and aftersales support

9.2 Contact

Email: Jessica@pairgears.com

Website: www.pairgears.com

10. Conclusion

Custom differential gear solutions are critical for applications where performance, durability, and accuracy are essential. At PairGears, we offer precision design, fast delivery, and top-tier support. Contact us to customize your drivetrain today.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.