Comprehensive Guide to Custom Shaft Services

1. Introduction

Rotating shafts are among the most fundamental components in mechanical power transmission systems. From cars and tractors to robotics and wind turbines, shafts ensure the smooth transfer of torque and rotational energy between components.

While standard shafts are widely available, industries with specialized requirements often turn to custom shaft services for tailored solutions. At PairGears, we provide end-to-end custom shaft manufacturing, enabling OEMs and equipment makers to optimize performance, durability, and reliability.

2. What Are Custom Shafts?

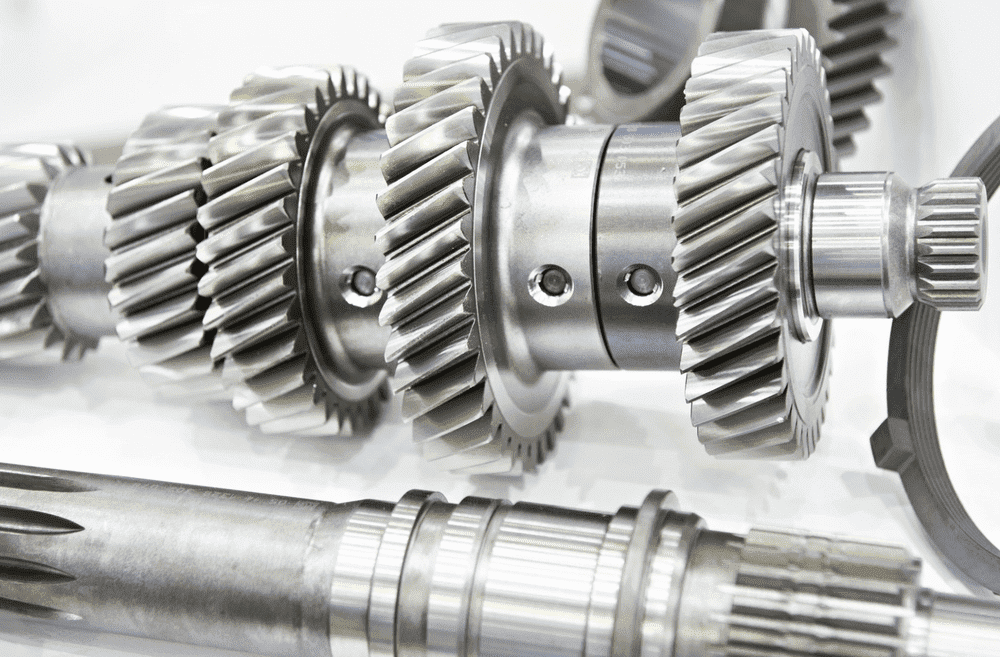

A custom shaft is a precision-engineered rotating component designed to meet unique application requirements. Unlike standard catalog options, custom shafts allow engineers to specify diameter, length, geometry, material, surface treatment, and tolerances.

Custom shafts are essential in applications where:

• High torque loads exceed standard shaft capabilities.

• Space constraints demand non-standard dimensions.

• Corrosive or extreme environments require special coatings.

• Precision assemblies such as robotics or aerospace demand ultra-tight tolerances.

3.1 Superior Fit and Function

By matching exact tolerances, custom shafts ensure perfect alignment with gears, bearings, and couplings, reducing wear and improving efficiency.

3.2 Increased Load Capacity

Custom designs can accommodate higher torque transmission, critical in agricultural machinery, mining trucks, and construction equipment.

3.3 Durability and Reliability

With advanced heat treatments like carburizing, nitriding, and chrome plating, custom shafts withstand fatigue, corrosion, and extreme environments.

3.4 Downtime Reduction

By minimizing premature failures, tailored shafts reduce maintenance frequency, ensuring longer uptime for critical machinery.

As a trusted transmission shaft manufacturer, PairGears offers full-spectrum services:

4.1 Tailored Design Solutions

• CAD/CAM support for both metric and imperial units.

• Integration of keyways, splines, and threads for seamless engagement.

Learn more about our Customized Precision Gears.

4.2 Wide Material Options

• Alloy Steels (4140, 4340) – strength and toughness.

• Stainless Steels (304, 316) – corrosion resistance.

• Bronze & Brass – anti-friction applications.

• Tool Steels – extreme wear resistance.

4.3 Advanced Machining Capabilities

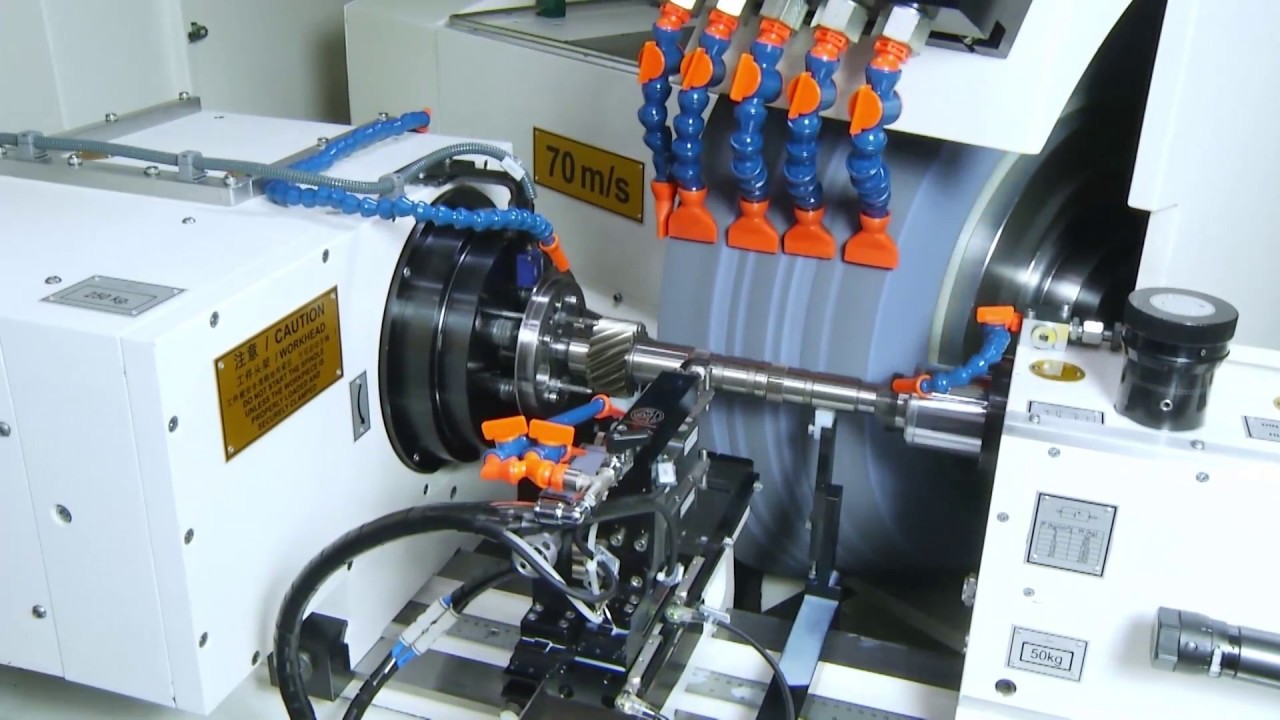

• Multi-axis CNC turning & milling for high precision.

• Cylindrical grinding & polishing for Ra < 0.8 μm.

• Tight tolerances down to ±0.005 mm.

4.4 Surface Treatments & Coatings

Black oxide, chrome plating, induction hardening, nitriding — extending both performance and aesthetics.

4.5 Rapid Turnaround

Lean scheduling and automated project tracking enable delivery from prototype to production in 10–25 days

5.1 Key Design Parameters

• Torsional strength & bending load.

• Bearing fit, alignment, and concentricity.

• Moment of inertia for dynamic stability.

5.2 Material Science

We evaluate machinability, heat resistance, fatigue strength, and cost to recommend the optimal alloy for each application.

5.3 Manufacturing Workflow

1. Raw material inspection.

2. CNC machining & turning.

3. Heat treatment (induction, carburizing).

4. Grinding, polishing, and coating.

5. Final inspection & certification.

See our Manufacturing Capabilities.

6. Quality Control at PairGears

We follow ISO 9001:2015 standards and rigorous in-house testing:

• CMM dimensional inspection.

• Surface roughness checks.

• Ultrasonic flaw detection.

• Hardness testing (Rockwell & Brinell).

7. Applications of Custom Shafts

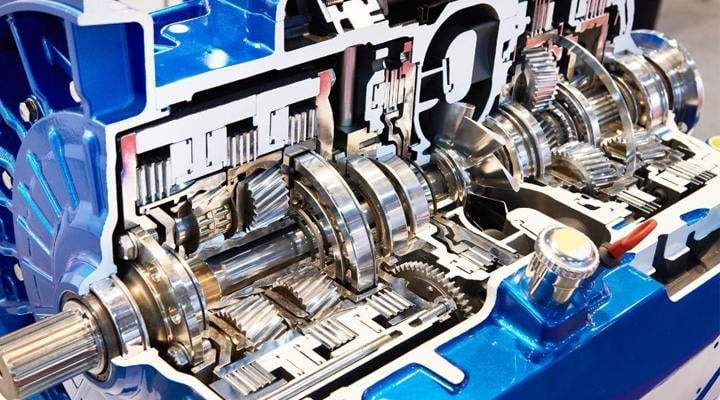

7.1 Automotive Industry

Drive shafts, gearbox main shafts, steering components.

7.2 Industrial Machinery

Conveyor rollers, packaging machine shafts, robotic arms.

7.3 Agriculture & Construction

Tractor PTO shafts, harvester shafts, hydraulic pump drives.

7.4 Renewable Energy

Wind turbine shafts, hydro-mechanical actuators.

7.5 Aerospace & Medical

Ultra-precision shafts in mission-critical systems.

8. Case Studies

8.1 Agricultural Equipment Manufacturer (Europe)

PairGears supplied nitrided drive shafts, reducing field failures by 30% within six months.

8.2 Robotics Firm (USA)

Delivered precision shafts with ±0.005 mm tolerances, improving assembly repeatability by 20%.

8.3 Wind Energy Project (Germany)

Developed large-diameter turbine shafts with optimized coatings, extending service life under high load cycles.

Q1: What is your minimum order quantity (MOQ)?

A1: Typically 10 units, depending on complexity. Contact us for custom quotes.

Q2: Can you provide prototypes?

A2: Yes, we offer prototyping services, including single-piece CNC runs.

Q3: How long is delivery?

A3: 10–25 working days depending on material and complexity.

Q4: What file formats do you accept for design?

A4: STEP, DWG, IGES, and SolidWorks formats are preferred.

Q5: Can shafts be marked with serial numbers or logos?

A5: Yes, laser engraving is available upon request.

10. Conclusion

Custom shafts are essential for modern industries demanding efficiency, durability, and high performance. From automotive gearboxes to renewable energy turbines, custom shaft machining ensures reliability where standard components fall short.

PairGears combines 15+ years of expertise, advanced CNC equipment, and strict quality control to deliver shafts that exceed global standards.

Contact us today to start your project.

📩 Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.