Comprehensive Guide to Custom Worm Gear Services

1. Introduction

1.1 What Are Worm Gears and Why Customization Matters

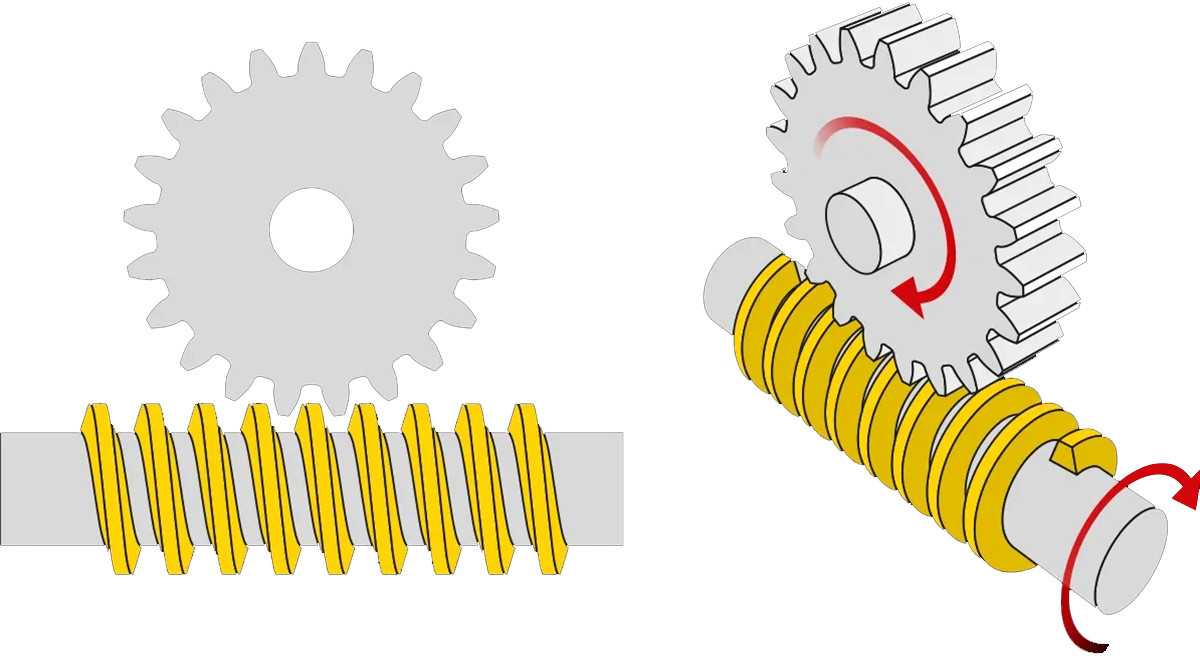

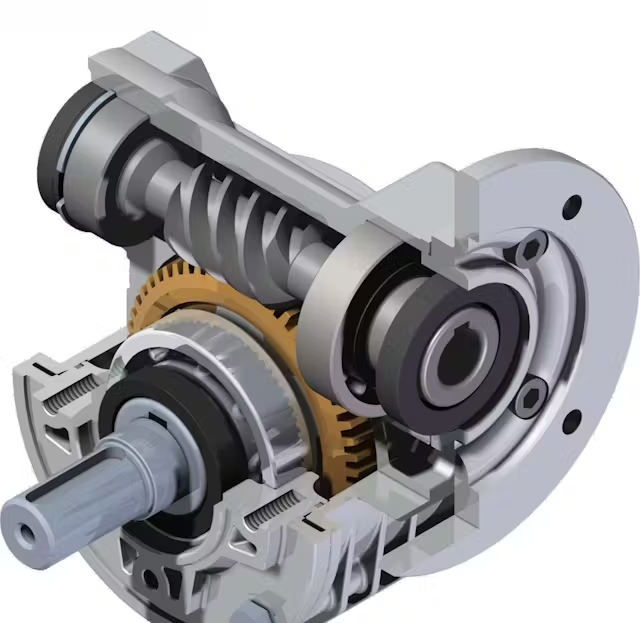

Worm gears are a type of gear system where a screw (the worm) meshes with a gear (the worm wheel), commonly used for high-reduction ratios and non-intersecting shafts. Unlike standard gears, custom worm gear design allows precise adjustment of speed, torque, and spatial configuration for unique applications.

1.2 Why Choose Custom Worm Gears?

Standard worm gears may not meet complex requirements in mechanical design. Custom worm gear manufacturing enables optimization of gear ratio, alignment, materials, and wear resistance. PairGears offers comprehensive solutions for industries needing durable and application-specific worm gear systems.

2. Advantages of Custom Worm Gears

2.1 Efficient Torque Reduction and Speed Control

Tailored gear ratios in worm gears provide high reduction with compact size.

2.2 Quiet and Smooth Operation

Custom tooth profile and materials minimize vibration and ensure quieter motion.

2.3 Improved Load Carrying and Wear Resistance

Using custom materials and treatments enhances load capacity and extends operational life.

3. Our Custom Worm Gear Services

3.1 Personalized Design

Each worm gear set is designed per customer specs: gear ratio, center distance, output shaft alignment, and direction of rotation.

3.2 Material Selection

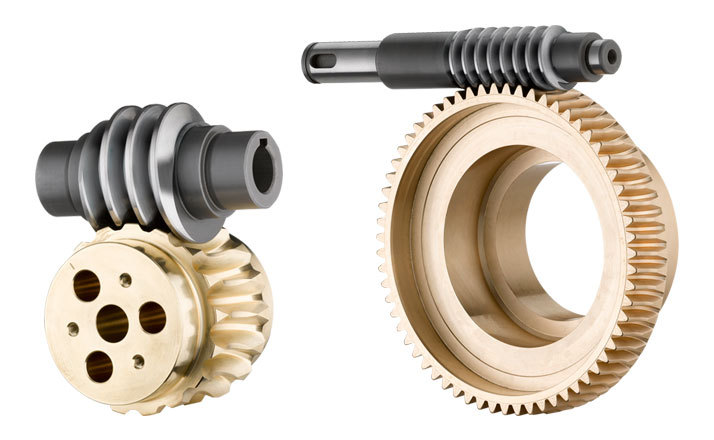

• Alloy Steel (e.g., 20CrMnTi, 42CrMo)

• Bronze alloys (e.g., ZCuSn10P1)

• Hardened steel for worms

• Plastic composites for low-noise or lightweight applications

3.3 Size & Gear Specifications

We support variations in:

• Module (metric or imperial)

• Number of teeth

• Lead angle and helix angle

• Shaft bore and mounting holes

3.4 Surface Treatments

• Nitriding

• Carburizing

• Black oxide or phosphate coating

• Precision grinding for gear flanks

3.5 Advanced Manufacturing

• CNC turning and worm thread grinding

• Worm wheel hobbing and finishing

• Thermal treatment for wear resistance

• In-house quality inspection before dispatch

3.6 Fast Turnaround

Efficient in-house tooling and engineering support allows us to offer custom worm gear solutions with short lead times.

4.1 Key Parameters

Including module, pressure angle, lead angle, center distance, and tooth width—each affects torque transfer, backlash, and heat dissipation.

4.2 Materials Science

Example: Bronze worm wheels reduce friction against steel worms. Plastic options help in noise-sensitive environments.

4.3 Manufacturing Workflow

From blank preparation to final testing:

4.3.1 CNC machining

4.3.2 Heat treatment

4.3.3 Gear finishing

4.3.4 Assembly and testing

4.4 Surface Finishing Importance

Correct finishing prevents micro-pitting, improves lubrication retention, and extends lifespan.

5.1 Stringent Quality Tests

• Gear profile and accuracy (AGMA/DIN standards)

• Hardness testing

• Dimensional tolerance inspection

• Tooth contact pattern evaluation

5.2 Digital Monitoring

Real-time feedback ensures adherence to spec at every step.

5.3 Third-Party Certification

We comply with international standards such as ISO 9001 and CE where required.

6. Applications

6.1 Automotive

Power seats, sunroof actuators, steering mechanisms.

6.2 Industrial Machinery

Packaging machines, conveyor systems, elevators.

6.3 Medical Equipment

MRI bed positioning, surgical robotics.

6.4 Renewable Energy

Solar tracking systems, small wind turbines.

6.5 Agricultural Equipment

Auger drives, feed mixers, and compact tractors.

7. Case Studies

7.1 Agricultural OEM

Custom bronze worm gear for feed mixing system, optimized for low maintenance.

7.2 Packaging Line

High-efficiency worm gear drive for synchronized motion.

7.2 Medical Devices:

Low-backlash worm gear for accurate table positioning.

Q1: Minimum order for custom worm gears?

A1: MOQ varies by spec—typically low-volume runs available. Contact us for quotes.

Q2: Delivery lead time?

A2: 10–25 business days based on complexity.

Q3: Can you provide samples?

A3: Yes, prototypes and samples can be arranged.

Q4: What if I need special coatings or shaft integration?

A4: We offer full customization of coatings and integrated components.

9. Start Your Project

9.1 Contact us via Contact Page

9.1.1 Submit drawing or requirements

9.1.2 Technical consultation & quotation

9.1.3 Confirm specs and initiate production

9.1.4 Delivery and aftersales support

9.2 Contact

Email: Jessica@pairgears.com

Website: www.pairgears.com

10. Conclusion

Custom worm gears are critical for precise, reliable motion in compact mechanisms. PairGears brings expertise, quality, and rapid delivery to every project. Contact us for your custom worm gear needs today.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.