Custom Bevel Gear Solutions for High-Performance Application

1.Introduction

At PairGears, we design and manufacture precision right-angle gearsets for agricultural machinery, heavy truck, construction equipment, and electric vehicle (EV). Catalog bevel gears rarely fit today's performance, packaging, and NVH targets. Custom bevel gear solutions—spiral, straight, or hypoid—let us tune geometry, metallurgy, and finishing so your drivetrain delivers quiet, durable, and efficient power.

2.Why custom bevel gear?

Off-the-shelf parts help with prototyping, but high-duty programs need tighter control over geometry, surface, and tolerances—and the ability to validate them.

Match the duty cycle: tooth form, contact ratio, and module sized to real torque/speed spectra.

Control NVH: micro-geometry (lead crown, profile relief) and mounting distance tuned to keep the contact pattern centered under load.

Increase life: deeper, more uniform case depth; clean steel; ground/honed flanks and superfinished journals.

Meet constraints: space envelope, bearing spans, shaft angles, thermal growth, and lubrication paths unique to your gearbox.

Harden for the environment: dust, mud, salt, or high temperature with the right heat-treat + surface engineering stack.

3.Choosing the right bevel type

| Type | Teeth & mesh | Best for | Notes |

| Straight bevel | Straight teeth, line contact | Low–moderate speed, simpler gearboxes | Lower cost; higher impact load at entry; louder at speed |

| Curved teeth, gradual contact | High speed/torque, low NVH | Smoother, higher contact ratio; tighter manufacturing | |

| Hypoid | Spiral + axis offset | High torque, tight packaging | More sliding; large single-stage ratios; lube selection critical |

PairGears tip: We map shaft angle, ratio, torque, speed, NVH target, oil strategy, and cost to an optimal choice, then freeze mounting distance and micro-geometry early.

4.Key design considerations

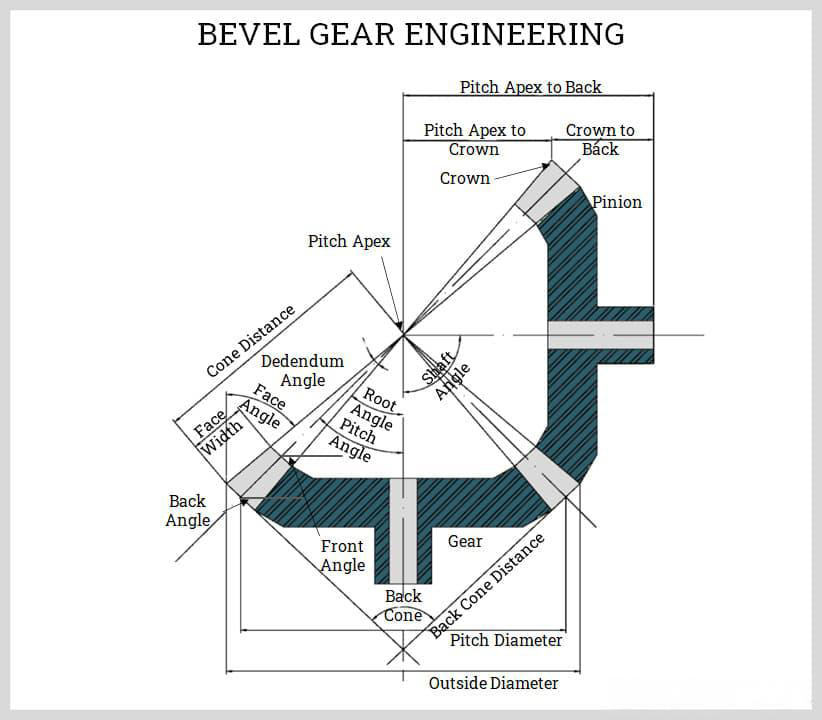

4.1 Gear geometry & micro-geometry

Module / DP, pressure angle, face width, spiral angle set capacity and efficiency.

Lead crowning and profile relief keep the contact patch away from edges under loaded deflection.

Define backlash windows for cold/hot and validate with contact pattern at operating temperature.

4.2 Materials & heat treatment

20MnCr5 / 18CrNiMo7-6 (carburized + ground): high contact strength, long life for trucks, construction, EVs.

42CrMo4 / 4140 (Q&T + induction): tough cores with selective hard tracks—cost-effective for agriculture/industrial.

38CrMoAlA (nitrided): low distortion for precision right-angle drives in automation.

On the drawing, specify effective case depth (Eht) windows, surface/core hardness, and retained austenite (for carburized sets).

Grinding/honing to flank Ra ~0.4–0.8 μm lowers run-in and tonal noise.

Superfinish journals where bearing heat is a concern.

Phosphate / DLC-like coatings help against fretting (splines) and corrosion.

4.4 Bearings, alignment, and lubrication

Bearing span and stiffness drive mesh stability; less deflection ⇒ more stable patterns.

Oil choice (viscosity, EP package) and delivery (splash vs. jets, jet angle/flow) matter as much as material.

5.Practical specification table

| Parameter | Typical target (tune per program) | Why it matters |

| Contact pattern | Centered & stable at operating load | Confirms mounting distance + micro-geometry |

| Surface hardness | HRC 58–62 (carburized), nitrided equivalent | Wear & pitting resistance |

| Eht (case depth) | Duty-matched; e.g., 0.8–1.4 mm for truck hypoids | Prevents subsurface fatigue |

Flank roughness | Ra 0.4–0.8 μm (ground/honed) | Lower noise, better oil film |

Runout to datum | ≤0.01–0.02 mm (gear & shaft seats) | Keeps pattern centered; reduces whine |

Backlash window | Per application & grade | Oil film + thermal growth margin |

PairGears will tune these to your torque, speed, duty cycle, temperature, and NVH targets.

6.Manufacturing process

Blank & conditioning — forged/rolled steel with controlled cleanliness; normalize/stress-relieve where needed.

Pre-cut machining — turn hubs/bores, establish datums, add lube features; control residual stress.

Tooth cutting — Gleason/Klingelnberg for spiral/hypoid; hobbing/shaping for straight bevels; skiving where geometry/volume allow.

Heat treatment — vacuum carburizing + gas quench (uniform case, low distortion), induction for selective hard tracks, nitriding for geometry stability.

Finishing — tooth grind/hone, journal OD grind, optional superfinish for NVH/bearing life.

Validation — tooth profile/lead/pitch charts; microhardness traverse & Eht; contact pattern at mounting distance; runout/concentricity to datums; spin-rig NVH if required; full traceability (steel heat, furnace load, cutters, gages).

7.Typical defects & how custom design prevents them

Edge loading / scuffing: Fix with proper crowning, correct mounting distance, and directed oil jets.

Pitting / micro-spalling: Increase Eht, improve flank finish, verify oil film thickness (viscosity/temp).

Whine at specific orders: Tighten runout, refine profile/lead, re-check bearing stiffness and preload.

Fretting at hub/spline: Deeper case under splines, anti-fretting coating, defined assembly lube and torque.

8.Applications we serve

8.1 Agricultural machinery

PTO drives, wheel ends, harvesters—mud/dust and shock dominate. We combine Q&T cores + induction or carburized & ground flanks, generous fillets, and sealed lube paths for durability and serviceability.

8.2 Heavy truck

Axles, transfer cases, PTOs—long life and strict NVH. We favor vacuum carburizing + hard grind + superfinish, tight runout to functional datums, and controlled micro-geometry for quiet, repeatable meshes.

Cranes, winches, slew drives—transient peaks and heat. Deep case, reinforced root radii, and optimized bearing spans keep patterns stable under load; oil jets reach the mesh at off-design duty.

E-axles and auxiliaries—high speed, very low noise floor. Low-scatter heat treat, honed/superfinished flanks, strict TIR, controlled backlash, and hot-condition pattern checks minimize whine across the band.

9.Case snapshot-custom hypoid pair for an EV e-axle

Challenge: Package a quiet, high-torque right-angle reduction in a compact EV e-axle with tight thermal limits and strict cabin NVH. Must handle launch torque spikes and continuous high RPM within fixed bearing spans.

Approach

Geometry: Hypoid spiral bevel pair with application-specific lead crowning and profile relief; backlash window tuned for oil film at temperature.

Metallurgy: Vacuum carburized 18CrNiMo7-6 with verified Eht and controlled retained austenite; core toughness validated by Charpy.

Finishing: Tooth grind + hone to Ra 0.4–0.6 μm; journals OD-ground and superfinished; runout to primary datums ≤0.01–0.02 mm.

Validation: Multi-load contact-pattern maps at mounting distance, thermal growth simulation across duty, spin-rig NVH checks, and full hardness traverse with Eht.

Results: Lower whine orders across the operating band, increased pitting-life margin, and reduced bearing temperature at endurance load—meeting OEM targets with reserve.

Performance metrics (EV e-axle hypoid)

| Metric | Requirement | Achieved |

Peak input speed | 14,000 rpm | 15,200 rpm |

Launch torque (mesh) | 2,200 Nm | 2,450 Nm |

Flank surface hardness | HRC 58–62 | HRC 61–62 |

Effective case depth (Eht) | 0.9–1.2 mm | 1.10 mm (±0.05 |

| Flank roughness (post-hone) | Ra ≤ 0.8 μm | Ra 0.5–0.6 μm |

| Pattern stability (hot) | Centered; no edge load | Pass |

| Spin-rig NVH (target orders) | ≤ spec | Pass with margin |

Predicted pitting life (L10) | ≥ target | +22% margin |

10.Future-ready trends

Advanced materials & cleanliness: tighter inclusion control and retained-austenite targets extend fatigue life.

Low-scatter heat treat: LPC + gas quench reduces distortion and finishing stock.

Process-aware micro-geometry: simulation closed-looped with real cut/grind data to set crowning right first time.

Smart QA: condition-based inspection frequencies and digital traceability tied to material/HT lots.

11.Conclusion

Custom bevel gears turn tight envelopes and harsh duty cycles into stable, high-value drives. The winning stack is consistent: fit-for-purpose geometry and micro-geometry, duty-matched metallurgy and heat treat, clean finishing, and evidence-based QA. That's how PairGears delivers quiet, durable performance—from the field and jobsite to long-haul routes and EV platforms.

Evaluating a bevel gear for your next right-angle drive—or upgrading a current design for life and NVH? Send us your drawing and duty cycle. Contact us.