How to Get Internal Splines to Fit Right the First Time?

1. Introduction

When customers first send us an internal spline drawing, the request is usually straightforward: “Please quote this part. Can you make the lead time short?” But when the parts reach the assembly line, different problems often appear. The shaft will not go in at all. Or it only fits with force. Or it slides in easily—but with unacceptable play. At that stage, price and delivery time are no longer the real issue. The real problem is that the first build failed.

Internal splines, seemingly "just teeth in a hole," actually must simultaneously perform three tasks: transmitting torque, precise positioning and alignment with the center shaft, and facilitating actual assembly and maintenance. Improper fit can disrupt assembly processes, affect delivery schedules, and sometimes even impact the entire machine or vehicle project.

This article, from our perspective, aims to explain why internal spline projects often fail on the first manufacturing attempt, the differences between PairGears' solutions and those of other factories, and what information can truly help us deliver perfectly fitted splines from the outset (not just on paper).

2. Why internal spline projects often "blow up"

From the manufacturing side, internal splines tend to fail for a few simple reasons. None of them are about “machine brand”.

2.1 Only a contour, no standard

Sometimes the drawing shows a tooth shape and some diameters, but does not clearly state:

-which tolerance class

-which inspection method

Different spline standards have different tooth forms, tolerance zones and gauging rules. Two splines that “look similar” on paper can behave very differently in assembly.

2.2 Fit is shown on paper, but not in real life

The drawing may show a nominal fit, but says nothing about:

-the actual shaft tolerance and surface finish

-whether you expect a sliding fit, light press fit or almost rigid fit

-how often you plan to assemble and disassemble

The result: the spline meets the drawing, but when you push the real shaft in, it is either too tight, too loose, or feels different from your existing parts.

2.3 Heat treatment distortion is ignored

Many internal splines are hardened (carburizing, induction hardening, quench-and-temper). If we do not allow for distortion, then:

-a“perfect”soft-spline size becomes wrong after hardening

-tooth form and bore roundness change together

-the fit to the shaft drifts out of your preferred zone

If the drawing only gives a final hardened size, but the process route is not discussed, the chance of rework increases a lot.

2.4 Gauging is not aligned

We sometimes see this situation:

-The supplier uses internal micrometers or basic gauges.

-The customer inspects with a go/no-go spline gauge or with the real shaft.

Both sides can be "right" according to their own method, but the parts still do not agree at assembly. Without a shared gauging method, argument is almost guaranteed.

3. Before cutting , we ask a few extra questions

At PairGears, we try not to "just make to print" on internal splines. For each new project we take a short step back and ask:

3.1 What system is this spline working in?

-What torque range and duty cycle? Is loading smooth, or full of shock loads?

3.2 What kind of fit do you really want?

-Very tight, rarely disassembled?

-Serviceable fit for maintenance?

-Torque mainly through the spline, or through key / interference, with the spline mostly centring?

3.3 Can you send a mating shaft or sample part?

-A real shaft plus an “old” spline part often tells us more than ten pages of drawings.

-We can measure the actual fit you like, then design tolerances and process around that.

3.4 Standard or legacy in-house profile?

-If it is a known standard, we follow that for cutting and gauging.

-If it is an old in-house design, we may suggest alignment with modern tooling, heat treatment and inspection methods.

While these additional issues may take some time initially, they ultimately save more time and effort, preventing many problems. The sooner we reach a consensus on "what a good component should look like and how it should function", the smoother the product manufacturing process will be.

4. From sample to mass production: how we control risk

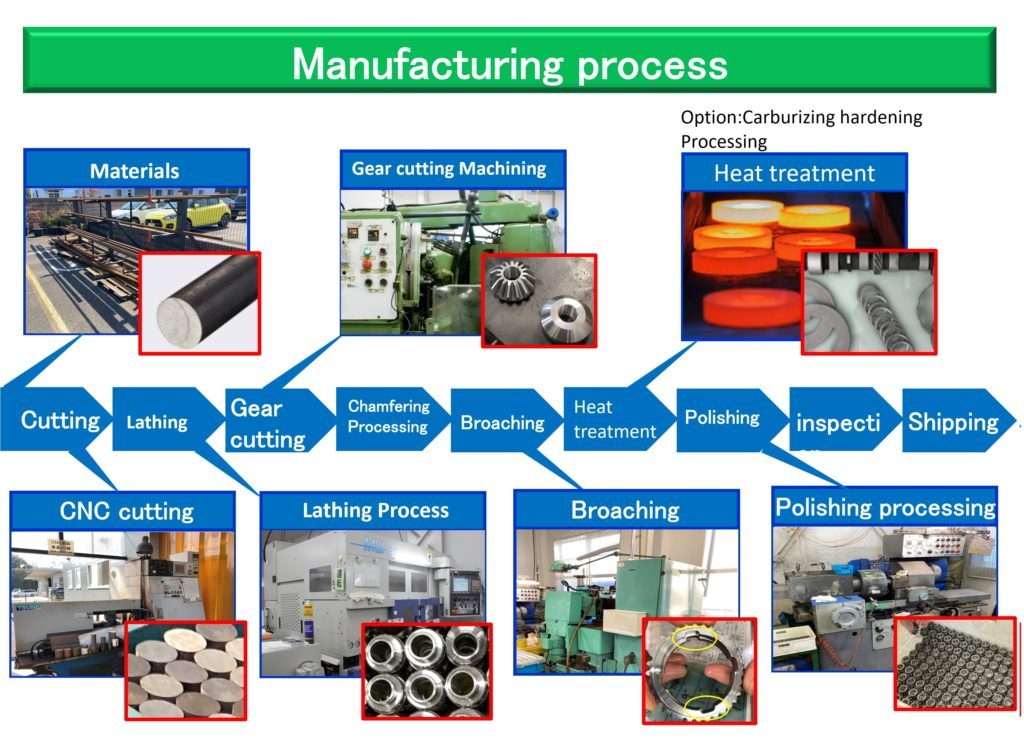

Here is how a typical internal spline coupling or hub moves through our factory.

| Stage | What we do | Why it matters |

Technical review | Check standard, torque, life, fit, material, heat treatment | Ensures design, process and expectations match |

Process design | Choose forming, cutting (shaping/broaching/skiving), heat treatment and finishing | Controls distortion and fit, not just nominal size |

| Sample build | Make trial parts, use customer shaft or gauge for test fits | Validates "feel" and function, not only drawing values |

| Process tuning | Adjust offsets, allowances and gauging based on sample data | Locks in a stable process window before mass production |

| Production control | Use dedicated gauges and SPC on key spline features | Keeps fit and function consistent over many batches |

For us, a successful internal spline project is not "we shipped the first batch". It is:

-the customer's shaft goes in smoothly on the first try

-assembly does not need special tricks

-the fit remains stable across batches and heat treatment lots

5. Practical tips for engineers and buyers

From a factory perspective, here are some very simple things that make internal spline projects smoother for everyone.

5.1 Put more clarity on the drawing

Where possible, specify:

-the spline standard or complete geometry data

-the intended type of fit to the mating shaft

-hardness and case-depth requirements

-whether the spline is the main torque path or mainly for centring

Even a brief note like “fit similar to existing part X” can guide us to ask the right follow-up questions.

5.2 Share mating parts or samples when you can

A real shaft, a worn sample or a current supplier's part gives us a real-world reference. We can:

-measure how it currently fits and wears

-see what you like and do not like

-propose realistic tolerance zones and process routes

5.3 Discuss heat treatment and gauging up front

Align as early as possible:

-heat treatment method and target hardness profile,acceptable distortion and where it matters most,which gauges will define “pass / fail” on both sides.

If you plan to check with a go/no-go gauge or trial shaft, we should know that before we lock the process, not after parts arrive.

5.4 Leave some budget for process, not just piece price

A short engineering call and one good sample round usually cost far less than:

-repeated rework,line stoppages due to fit issues,arguments about “who is right” on measurements.

For critical internal splines, the value is not "cheapest piece price today", but "no surprises on the day you build the machine".

6. Conclusion: Good internal splines come from clear conversations

Internal splines are not complicated parts by themselves. A good result usually comes down to three basics: clearly defined geometry and fit, a realistic process route from cutting to heat treatment and finishing, and an agreed way to measure and judge what a "good spline" actually is. Problems rarely come from a lack of machining capability, but from missing conversations at the start—standards were assumed, fits were not confirmed, and inspection methods were never aligned.

At PairGears, we try to move those conversations forward. We would rather ask a few extra questions, run a trial fit, and adjust once on the shop floor than deliver parts that look correct on a drawing but fail during assembly.

If you are developing a new internal spline, or struggling with splines that are too tight, too loose, or inconsistent, Contact Us with your drawing, mating shaft, and basic duty information. We review every project from one practical question that matters most in real production: can it be assembled smoothly the first time—and stay reliable over its service life?

FAQ: Internal spline projects with PairGears

Q1: What information do you need to quote an internal spline?

We usually need the drawing (or standard reference), material, heat treatment, target fit with the mating shaft, expected torque and duty cycle, annual volume and whether you can provide a sample shaft or existing part for reference.

Q2: Can you help if our current spline has fit problems?

Yes. If you send us shafts and sample parts, we can measure the actual geometry and fit, review your current drawing and process, and then suggest adjusted tolerances, process routes and gauging to stabilise assembly.

Q3: How many samples do you recommend before mass production?

For important internal splines, we usually suggest a small pilot batch for test assembly and functional checks. Once the fit and performance are confirmed, we freeze the process for series production.

Q4: Do you follow international spline standards?

We can work to ISO, DIN and other major spline standards, as well as customer-specific specifications. In each case we align cutting, heat treatment and inspection methods with the selected standard so that drawings, gauges and parts tell the same story.