Rack & Pinion Steering: Why the Pinion Gear Matters

1. Introduction

Rack and pinion steering looks simple: turn the steering wheel, the wheels change direction. Yet steering complaints—noise, looseness, tight spots, early wear—often come from small details hidden inside the gear mesh.

At PairGears, we support global customers across agricultural machinery, heavy-duty truck, construction equipment, and electric vehicle with high-quality power transmission solutions. In all these applications, the same rule applies: when motion is transferred through gear contact, tiny deviations in geometry or heat-treatment stability can show up quickly in real performance.

This article explains rack and pinion steering in plain language and highlights the part that most often defines steering feel and durability: the pinion gear.

2. Rack & Pinion Steering in Plain Language

Rack and pinion steering converts rotation into linear movement:

-The steering shaft turns a pinion gear (a small round gear).

-The pinion meshes with a straight toothed bar called the rack.

-As the pinion rotates, the rack slides left or right.

-Tie rods transfer that movement to the steering knuckles, and the wheels turn.

Because the power path is short and direct, the system can feel responsive. That also means there's less "buffer" to hide errors—if the gear mesh is not stable, drivers will notice.

3. The Key Components

Steering wheel: driver input

Steering shaft: transfers rotation

Pinion gear: drives the rack

Rack: moves left/right

Tie rods: pass rack movement to the wheel end

Steering knuckles: turn the wheels

4. How the System Works (Step-by-Step)

1.Driver input: steering wheel rotation turns the steering shaft.

2.Pinion rotation: the pinion gear rotates with the shaft.

3.Rack movement: pinion teeth push against rack teeth, sliding the rack left/right.

4.Tie rod action: rack motion pushes/pulls tie rods.

5.Wheel turning: tie rods rotate the steering knuckles, changing wheel direction.

A practical takeaway: the rack and pinion are always meshing, so contact quality matters continuously—not only under peak loads.

5. Why the Pinion Gear Matters More Than People Expect

Most steering "feel" is decided by gear contact behavior. The pinion gear is where that behavior starts.

5.1 Tooth geometry controls smoothness

A pinion gear is not just "teeth on a circle" Its performance depends on measurable geometry:

Profile (involute shape)

Lead (alignment across the face width)

Micro-modifications (relief/crowning when required)

If profile/lead is off, contact becomes unstable. That can show up as whine, vibration, or a gritty feel near center.

5.2 Backlash balances free play and binding

Backlash is the clearance between meshing teeth:

-Too much can feel loose or knock.

-Too little can bind, heat up, and wear faster (especially with temperature changes).

Backlash also interacts with bearing preload and housing stiffness, so defining measurement conditions early prevents disputes later.

5.3 Heat treatment can shift a "good" gear into a "bad" gear

Even if a pinion is accurate after cutting, heat treatment can introduce distortion or hardness inconsistency. In steering, small distortions can change contact pattern and noise behavior. That's why the manufacturing plan must treat heat treatment and inspection as part of the final performance outcome.

6. Common Field Symptoms

-Whine/click during steering: contact instability, rough tooth surface, geometry deviation

-Dead zone around center: excessive backlash, wear, tolerance stack-up

-Uneven effort / tight spots: runout, lead error, distortion after heat treatment

-Early wear / pitting / scoring: hardness or case depth issues, surface finish, lubrication/contamination

Most failures come from small deviations accumulating across cutting → heat treatment → finishing → inspection.

7. What to Specify When Sourcing a Steering Pinion Gear

A clear RFQ reduces risk and speeds up quoting. Use this practical checklist to align engineering intent with manufacturable control.

RFQ & Drawing Checklist (Table)

| Item to Define | What to Include (Examples) | Why It Matters |

Gear basics | module/DP, tooth count, pressure angle, helix angle/direction | Ensures correct mesh with the rack |

Tooth quality targets | profile/lead grade, composite error or equivalent | Directly impacts noise and smoothness |

Backlash window (if defined) | target range + measurement condition | Prevents looseness or binding |

| Datums & runout | datum scheme; runout to bearing seats/shaft axis | Avoids tight spots and uneven effort |

| Material + heat treatment | steel grade, hardness range, case depth (if carburized) | Drives wear life and fatigue resistance |

| Documentation | material certs, hardness/case report, gear inspection report | Supports incoming inspection and traceability |

If you don't have all of these, send what you do have. A good supplier should help clarify what is truly critical for function.

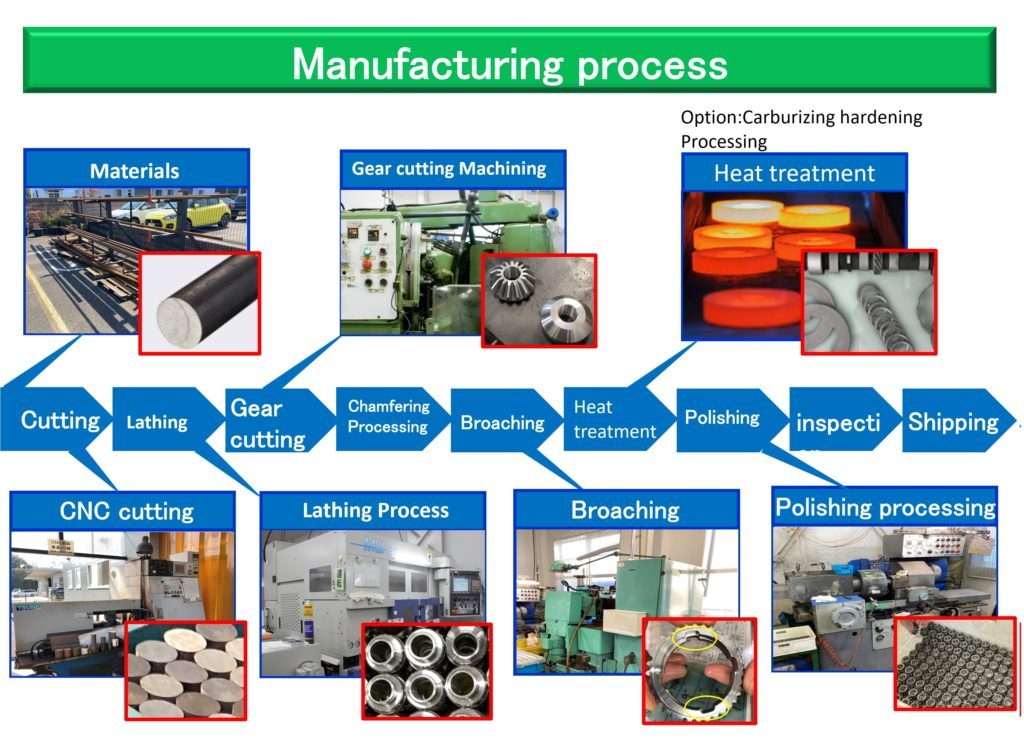

8. How PairGears Approaches Pinion Gear Manufacturing

PairGears is a precision gear manufacturer and custom gear supplier. For steering pinion gears and similar transmission parts, we focus on process stability—so geometry stays stable after heat treatment and in service.

Function-first drawing review

We confirm datums, critical fits, and which features drive noise/feel and assembly stability.

Stable references in early machining

We control concentricity and carry consistent datums through the process chain to avoid "it measured fine in one setup" problems.

Tooth cutting with downstream stability in mind

We plan cutting so the gear can hold contact quality after heat treatment, and support finishing when requirements demand it.

Heat treatment with distortion awareness

We verify hardness (and case depth when applicable) and monitor distortion risks that can shift tooth contact.

Inspection tied to functional risk

We check what customers actually feel: geometry stability, runout to defined datums, and critical interface fits—then provide aligned reports.

9. Ready to Quote? Here's What to Send

For a fast, accurate quotation, please share:

2D drawing (and 3D model if available)

quantity and target lead time

material + heat treatment requirements (or duty cycle if specs are open)

key focus: noise, backlash, runout, tooth contact, or assembly issues

When you're ready, Contact Us with your drawing and application notes. We'll respond with a manufacturable plan and quotation.

10. Conclusion

Rack and pinion steering is popular because it's direct, compact, and responsive. But that directness also makes it sensitive: small deviations in tooth geometry, backlash control, surface condition, or heat-treatment stability can become real-world noise, looseness, or early wear.

That's why the pinion gear matters. When it's produced with stable datums, disciplined heat treatment, and inspection matched to functional risk, the steering system becomes smoother, quieter, and more reliable over time.

FAQ

1.What does rack and pinion steering do?

It converts steering wheel rotation into left/right rack movement that turns the wheels.

2.Why does the pinion gear affect steering feel so much?

It directly controls tooth contact behavior and backlash, which drive smoothness, noise, and wear.

3.What causes free play in a rack and pinion system?

Often excessive backlash, wear, or tolerance stack-up in bearings and joints.

4.Why can replacement parts become noisy?

Common causes include unstable tooth contact, rough tooth surface, distortion after heat treatment, or incorrect backlash conditions.

5.Do all steering pinion gears need grinding?

Not always. It depends on accuracy/NVH targets and how well geometry remains stable after heat treatment.

6.What do you need for a quotation?

Drawing/3D model, quantity, material/heat treatment, and any focus areas such as noise, backlash, or runout.