Understanding Spur Gears: Design, Materials, and Real-World

1.Introduction

At PairGears, a precision gear manufacturer and custom gear supplier, we design and produce transmission components for agricultural machinery, heavy trucks, construction equipment, and electric vehicles (EVs). Among the many gear types we manufacture, spur gears remain the most common—and for good reason.

With a straightforward geometry, high efficiency, and cost-effective manufacturing process, spur gears are the workhorses of countless machines. This article takes you through their structure, materials, design considerations, and key applications, helping you understand why spur gears are still indispensable in modern power transmission systems.

2.What Is a Spur Gear?

A spur gear is a cylindrical gear with teeth that are straight and parallel to the axis of rotation. These teeth engage with those of another gear on a parallel shaft, allowing smooth torque transmission.

The main components include:

Pitch circle: the effective contact circle between mating gears.

Addendum and dedendum circles: define the outer and root boundaries of the gear tooth.

Face width: the axial width of the gear that determines load capacity.

Because of their simplicity, spur gears are easy to design, manufacture, and maintain—making them ideal for moderate-speed, high-efficiency systems where noise control is secondary.

3.Key Characteristics of Spur Gear

| Characteristic | Description |

Straight Teeth | Teeth are parallel to the gear's axis, ensuring efficient power transmission. |

Simple Design | Straightforward structure makes spur gear easy to manufacture. |

| Efficiency | Spur gear offer high efficiency in power transmission. |

| Ease of Maintenance | Simple design allows for easy inspection and maintenance. |

| Noise | Can be noisy at high speeds due to sudden engagement of teeth. |

4. Advantages and Trade-Offs

Advantages

High transmission efficiency (up to 98%).

Simple structure and easy maintenance.

Compact and cost-effective for high-volume production.

Excellent for precise, consistent motion between parallel shafts.

Trade-Offs

Noise and vibration (NVH) increase at high speeds due to sudden tooth engagement.

Less tooth overlap means higher stress per tooth compared with helical gears.

Limited to parallel shaft arrangements only.

Despite these limitations, spur gears remain unbeatable for durability, precision, and affordability when properly designed and heat-treated.

5. Classification of Spur Gears

Spur gears can be divided into different types according to multiple classification standards. The key criteria include the material used for manufacturing, the shape of their tooth profiles, and the way they are mounted in mechanical systems.

6. Classification by Manufacturing Material

6.1.Metal Spur Gears

These gears are fabricated using metallic materials such as steel, brass, and aluminum. Their primary advantages lie in high structural strength and long-term durability, making them suitable for high-load mechanical applications.

6.2 Plastic Spur Gears

Produced from plastic raw materials like nylon and polycarbonate, these gears stand out for their lightweight design. They also offer a cost-efficient solution, especially for low-torque and low-speed operating scenarios.

6.3 Composite Spur Gears

This type is made by combining two or more different materials. The goal is to integrate the advantages of each component—for example, metal-plastic composites often combine the strength of metal with the lightweight property of plastic.

7.Composite Spur Gears

7.1 Straight-Tooth Spur Gears

As the most widely used type of spur gear, their teeth are designed to be straight and parallel to the gear's central axis. They are favored for their simple structure and easy manufacturing process.

7.2 Helical Spur Gears

Unlike straight-tooth gears, their teeth are cut at a specific angle relative to the gear's axis. This angled design enables smoother power transmission and significantly reduces operating noise compared to straight-tooth variants.

8. Classification by Mounting Configuration

8.1 Internal Spur Gears

The teeth of these gears are distributed on the inner wall of a cylindrical structure. They are typically used in planetary gear systems, where they act as fixed or rotating ring gears to adjust power output.

8.2 External Spur Gears

With teeth arranged on the outer surface of a cylinder, this is the most common mounting configuration for spur gears. They are widely applied in various mechanical drives to transfer power between parallel shafts.

9.Comparison of Different Types of Spur Gear

| Type | Description | Advantages |

| Metal Spur Gear | Made from metals like steel, brass, aluminum | High strength, durability |

| Plastic Spur Gear | Made from plastics like nylon, polycarbonate | Lightweight, cost-effective |

| Composite Spur Gear | Combination of materials | Balanced properties |

Straight-Tooth Spur Gear | Straight, parallel teeth | Simplicity, easy manufacturing |

Helical Spur Gear | Teeth at an angle | Smoother, quieter operation |

Internal Spur Gear | Teeth on the inside of a cylinder | Compact design, used in planetary systems |

External Spur Gear | Teeth on the outside of a cylinder | Common configuration, versatile |

10.Four Key Industries We Serve

10.1 Agricultural Machinery

Spur gears find extensive application in critical agricultural equipment, including tractor transmission systems, power take-off (PTO) drives, and combine harvesters. These settings are typically characterized by harsh conditions such as dust accumulation, high humidity, and frequent shock loads. To address these challenges, PairGears prioritizes two key performance metrics: fatigue resistance and surface wear prevention. We achieve this by refining gear micro-geometry and enhancing lubrication system designs, ultimately extending the gears’ service life in field operations and minimizing maintenance-related downtime.

10.2 Heavy Trucks

Within the gearboxes and differentials of heavy trucks, spur gears serve as a vital component in auxiliary gear trains and reverse gear mechanisms. Our engineering team leverages finite element analysis (FEA) to optimize gear performance. Specifically, we reduce stress concentrations at the gear root and fine-tune contact ratios, ensuring the gears maintain stable performance even under extreme conditions like high torque output and significant thermal stress.

10.3 Construction Equipment

Gears used in construction machinery—such as excavators, cranes, and concrete mixers—must withstand intermittent shock forces and repeated cycles of heavy loading. PairGears enhances the durability of these gears through two targeted measures: reinforcing the tooth root structure and applying customized heat treatment processes. These improvements enable the gears to maintain reliable operation, even in contaminated work environments where mud and water ingress are common.

10.4 Electric Vehicles (EVs)

While helical gears and planetary gear systems are the primary choices for most EV gear reducers, spur gears remain indispensable in low-speed reduction stages. In these stages, factors like structural simplicity, compact design, and minimal backlash are critical. PairGears supplies small-module spur gears that feature lightweight construction and precision grinding. These gears meet the strict industry standards for noise, vibration, and harshness (NVH) control, as well as the high-efficiency requirements of next-generation EV drive systems.

11.Material Selection and Heat Treatment

The performance and lifespan of spur gears largely depend on material choice and heat treatment. At PairGears, we tailor these parameters for each application.

| Application | Recommended Material | Heat Treatment | Key Benefits |

| High torque (trucks, construction) | 20CrMnTi / 18CrNiMo7-6 | Carburizing + quench + temper | Deep case, high contact strength |

| Medium load (agriculture) | 45# / 40Cr | Induction hardening | Good toughness, easy machining |

| Precision gear (EVs, automation) | 38CrMoAl | Nitriding | Low distortion, high surface hardness |

Low load / quiet drive | POM, PA, PEEK | Surface coating or none | Lightweight, low noise, corrosion-resistant |

Proper heat treatment—like carburizing, nitriding, or induction hardening—ensures that the tooth surface is wear-resistant while the core maintains enough toughness to absorb impact loads.

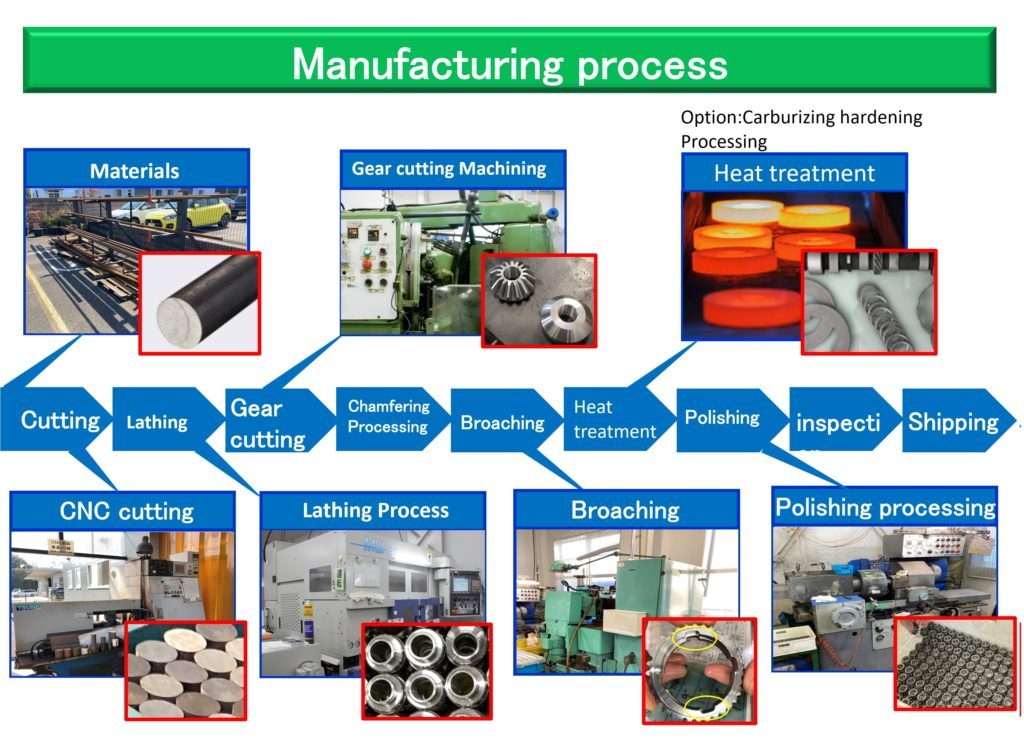

12. Manufacturing Process Overview

1.Blank preparation: Forged or rolled steel ensures uniform density and fewer defects.

2.Rough machining: Turning and milling set the basic geometry.

3.Gear cutting: Typically done by hobbing, followed by shaving or skiving for fine adjustment.

4.Heat treatment: Increases surface hardness and fatigue strength.

5.Finishing: Grinding or honing reduces surface roughness and noise.

6.Inspection: Tooth profile, lead, runout, hardness, and contact pattern are verified before packaging.

Modern processes, like dry hobbing and vacuum carburizing, also align with PairGears'commitment to green manufacturing and energy efficiency.

13. Common Gear Defects and How to Avoid Them

Pitting: caused by overload or poor lubrication — prevent with proper hardness and surface finish.

Tooth breakage: avoid by ensuring strong root fillets and proper material toughness.

Scuffing: use correct lubrication and ensure accurate surface finishing.

Vibration marks: check clamping rigidity and reduce cutting forces during machining.

At PairGears, each gear undergoes contact pattern analysis and microhardness testing to ensure it meets strict dimensional and mechanical requirements before shipment.

14. Manufacturing and Quality Control

High-quality spur gears depend on both equipment capability and process discipline.

PairGears integrates CNC gear hobbing, shaving, and grinding with advanced inspection systems to ensure dimensional precision and repeatability.

Our inspection criteria cover:

1.Profile and lead deviation

2.Surface roughness and hardness

3.Dimensional and concentric accuracy

4.Dynamic contact pattern tests

All gears undergo 100% critical parameter inspection before packaging, accompanied by material and heat treatment certificates for full traceability — a core commitment in our precision gear manufacturing process.

15.Conclusion

Spur gears remain one of the most versatile and dependable components in modern machinery. Their simplicity and efficiency make them ideal for power transmission across diverse applications — from farm tractors and heavy trucks to construction cranes and electric vehicles.

At PairGears, we combine advanced gear manufacturing, precision grinding, and application-specific engineering to deliver reliable, durable, and efficient spur gears tailored to your system's needs.Contact us.