Why Are Bevel Gears Essential in Modern Power Transmission?

1. Introduction

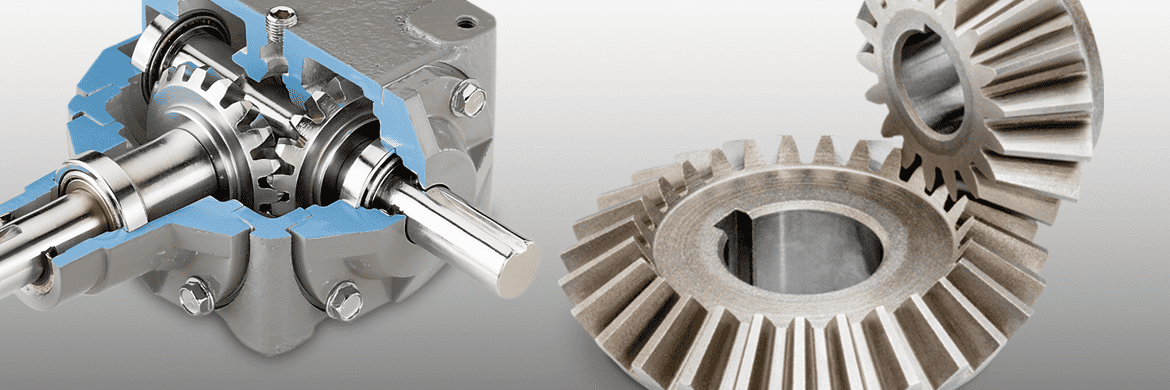

Bevel gears are a cornerstone of mechanical power transmission systems, enabling efficient torque transfer between intersecting shafts. Unlike spur or helical gears, bevel gears feature conical-shaped teeth that allow them to change the axis of rotation, typically at right angles. Their unique geometry makes them indispensable across industries ranging from automotive and agricultural machinery to robotics and aerospace.

As manufacturers and engineers search for the most reliable bevel gear supplier, understanding the design, advantages, and applications of these gears is critical. This article provides a comprehensive breakdown of bevel gears, why they matter, and how to select the right partner for your gear sourcing needs.

2. What Are Bevel Gears?

2.1 Definition and Geometry

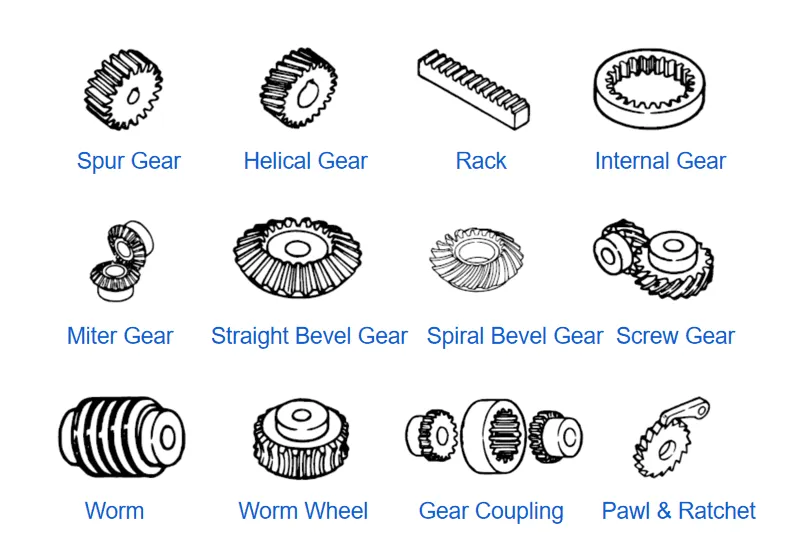

Bevel gears are mechanical components with teeth cut on a conical surface, allowing shafts to intersect—commonly at 90°, though other angles are also possible. According to Wikipedia, bevel gears are classified into several types, including:

• Straight bevel gears – simplest design with straight teeth.

• Spiral bevel gears – curved teeth for smoother and quieter operation.

2.2 How They Work

When two bevel gears mesh, rotational motion transfers between intersecting shafts, altering torque and speed ratios. This makes them critical in gearboxes, differentials, and industrial machinery.

3. Advantages of Bevel Gears

3.1 High Efficiency

Bevel gears are highly efficient in transferring torque across perpendicular axes. Their direct tooth engagement minimizes energy loss, an important factor in electric vehicles, trucks, and agricultural tractors.

3.2 Compact Design

Because bevel gears can change the axis of rotation within a small envelope, they are ideal for applications where space-saving design is essential, such as in robotic joints and aerospace systems.

3.3 High Load Capacity

Bevel gears, especially spiral and hypoid designs, are engineered to handle heavy loads at varying speeds. This makes them critical in truck differentials, mining equipment, and cranes.

3.4 Versatility

They can be designed for different gear ratios, offering flexibility for both high-torque and high-speed applications.

4. Applications of Bevel Gears

4.1 Automotive Sector

• Differentials: Hypoid bevel gears allow wheels to rotate at different speeds while maintaining torque delivery.

• Manual Transmissions: Spiral bevel gears help reduce noise while maintaining durability.

4.2 Agricultural Machinery

Tractors and harvesters use bevel gears to transmit power at varying angles, ensuring efficient performance in rugged conditions.

4.3 Robotics and Automation

Compact bevel gears provide precise motion control in robotic arms, AGVs, and humanoid robots.

4.4 Aerospace and Defense

Bevel gears are found in helicopter transmissions, drone mechanisms, and defense machinery, where reliability is critical.

Learn more about our custom precision gears.

5. Bevel Gears vs Other Gear Types

5.1 Compared to Spur Gears

Spur gears cannot change the axis of rotation, while bevel gears provide angular torque transfer.

5.2 Compared to Helical Gears

Helical gears are quieter but less efficient in intersecting shaft applications. Bevel gears balance efficiency and angular adaptability.

5.3 Compared to Worm Gears

Worm gears achieve high reduction ratios but suffer from lower efficiency. Bevel gears are superior in energy transfer for most power transmission needs.

6. Considerations When Selecting a Bevel Gear Supplier

6.1 Manufacturing Capability

A reliable bevel gear supplier should have CNC machining, Gleason grinding, and advanced heat treatment capabilities.

6.2 Material Selection

Suppliers must offer materials like 20CrMnTi, SCM415, and case-hardened steels to ensure durability.

6.3 Quality Control

Look for suppliers with certifications such as ISO/TS 16949 and advanced CMM gear inspection systems.

6.4 Customization and R&D

OEMs benefit from suppliers who can provide tailored designs, rapid prototyping, and flexible MOQ.

Explore PairGears R&D and Design.

7. Industry Trends and Future of Bevel Gears

7.1 Electric Vehicles (EVs)

EVs are driving demand for lightweight, high-efficiency bevel gears in both drivetrains and auxiliary systems.

7.2 Robotics

As humanoid and industrial robots scale up production, precision bevel gears are becoming essential.

7.3 Renewable Energy

Bevel gears are increasingly used in wind turbines and solar tracking systems, where efficiency is paramount.

8. Conclusion

Bevel gears remain one of the most versatile and essential components in power transmission systems. From truck differentials to robotic joints, they enable efficiency, compactness, and durability in demanding industries.

When selecting a partner, choosing the right bevel gear supplier can determine the long-term reliability and performance of your equipment. PairGears, with its expertise in custom precision gears, stands out as a trusted partner for OEMs across automotive, agricultural, and industrial sectors.For inquiries or to discuss your specific gear requirements, please contact us.