Why Gear Tolerance Matters in Precision Gear Design

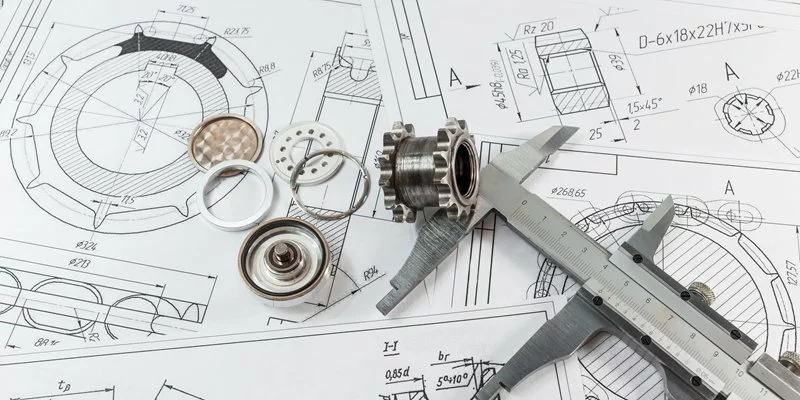

Introduction

As a specialist in custom gear manufacturing for industrial gears, I often get asked: “Why not make the precision gears as tight as possible?” Here’s what most clients don’t realize: tight isn't always right. In reality, tolerance stacking, assembly misalignment, and cost constraints drive the final decisions—not just specifying the smallest possible tolerances.

In transmission gears, over-specifying tolerances can inflate cost, lengthen lead times, and introduce handling complexity. Understanding what truly makes a gear functional helps clients work better with gear suppliers, reduce waste, and keep product workflows efficient.

1. What is Tolerance Stacking and Why It Matters

Tolerance stacking, or tolerance stack-up, refers to the accumulation of individual part variations in an assembled product. The sum of these variations can lead to misfit, binding, or unwanted gaps.For example, a gear shaft, housing bore, flange thickness, and face width—each with its own tolerance—together define the final alignment and backlash of a transmission gear set.

Worst-case stack-up analysis assumes all parts are at extreme tolerance limits—often resulting in overly conservative fits requiring ultra-tight tolerances and driving up manufacturing cost. Statistical methods (RSS or Monte Carlo) provide more realistic variation expectations that lower manufacturing expense while ensuring proper assembly.

2. Precision Gear Tolerances: When Tight Goes Too Far

A precision gear with ultra-tight tolerances (e.g. ISO Grade 4) may seem ideal—but if the housing bore or mating shaft is loose or misaligned, the gear still won’t run true. Reduced shock resistance, assembly binding risk, and unnecessary cost are inevitable.

Moreover, manufacturing and inspection cost escalate exponentially with tighter tolerance requirements. Modern tolerance analysis shows that tighter specs do not always proportionally increase performance—but do incur more scrap, longer lead times, and greater inspection overhead.

3. The Real-world Impact: Assembly, Cost & Functional Fit

3.1 Assembly Misalignment vs Manufactured Accuracy

Even if your industrial gears are within spec, poor assembly sequence or fixturing can induce errors. Designers must consider how parts fit during assembly: mating surfaces, alignment pins, and backlash designs. Failing to account for tolerance stacking during assembly planning leads to parts that technically meet drawing specs but fail to function smoothly.

3.2 Cost Implications

Tighter tolerances mean:

• Longer machining cycles and more tool wear

• Higher scrap rates during prototyping and first-off inspection

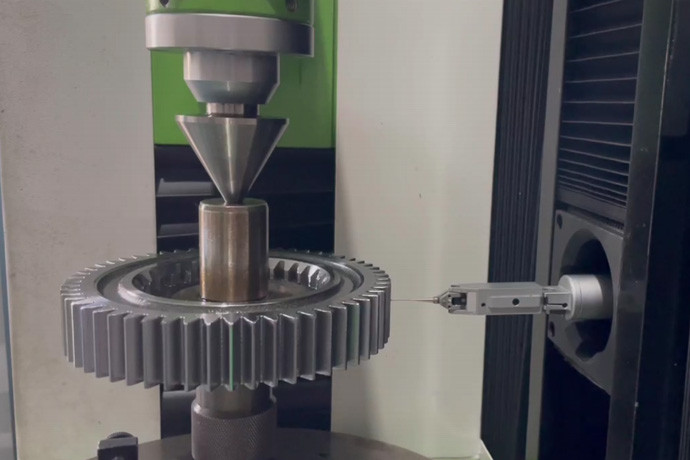

• Increased inspection time or expensive metrology equipment

• Statistical sampling vs 100% inspection decision greatly affects economics

Proper tolerance analysis helps you identify functional dimensions—those that affect gear meshing or backlash—and set tighter tolerances only where needed, while allowing broader tolerances elsewhere to reduce cost.

4. Recommendations for Clients Working with Gear Suppliers

4.1 Define Functional Requirements First

Identify what truly affects gear performance: backlash, runout, tooth thickness, face width. Base tolerance decisions on these, not arbitrary tight tolerances.

4.2 Ask for Tolerance Analysis

Ensure your gear suppliers provide tolerance stack-up reports: worst-case and statistical analysis models demonstrate how tolerances accumulate in the final assembly.

4.3 Align Tolerances with Process Capabilities

If your supplier conducts custom gear manufacturing, they should know the achievable tolerances based on their CNC, grinding, and inspection equipment. Over-demanding tolerances beyond capability leads to mistakes or costly rework.

4.4 Balanced Approach over Worst Case

Unless your application is safety-critical, avoid insisting on worst-case tolerancing across all components. Statistical tolerancing offers flexibility and cost savings while maintaining assembly integrity.

4.5 Include Inspection Strategy Upfront

Discuss inspection frequency early—statistical sampling can cut inspection costs without lowering quality, but only if tolerances are properly defined and functional.

5. Why PairGears Cares About Smart Tolerancing

At PairGears, we specialize in precision gears, transmission gears, and industrial gears. Our process includes:

• Functional requirement mapping: we tailor custom gear manufacturing to what truly matters.

• Tolerance analysis: both worst-case and statistical models are applied to assemblies.

• Process capability matching: tolerances specified to suit our CNC, gear grinding, and proscribed heat treatments.

• Cost-sensitivity: optimizing cost vs performance across all components.

We’ve seen clients try to over-specify every dimension only to see higher scrap, longer lead times, and assembly headaches—but not better gear mesh. Our guidance helps them eliminate unnecessary tight tolerances, controlling cost while ensuring functional quality.

Conclusion

If you ask “What is a precision gear?”, the answer goes beyond its nominal dimension control. It’s about how that gear fits within its assembly—with tolerance stacking accounted for—and how its cost is justified by performance.

So please remember: tight isn't always right. The smarter path is designing for fit and function—via tolerance stack-up awareness, assembly planning, and cost-effective precision. If you're evaluating gear suppliers or specifying transmission gears, ask them: “Can you show a tolerance stack-up analysis and propose functional tolerances?”

At PairGears, we’re happy to help clients optimize gear tolerance specifications across the design-to-manufacturing workflow.

Please contact us to discuss how tolerance strategy can improve performance and reduce cost in your next project.